The climate objective to reduce CO2 emissions in Belgium by 80% by 2050 compared to 2005 levels is a major challenge and requires a large-scale switch from fossil fuels to renewable energy.

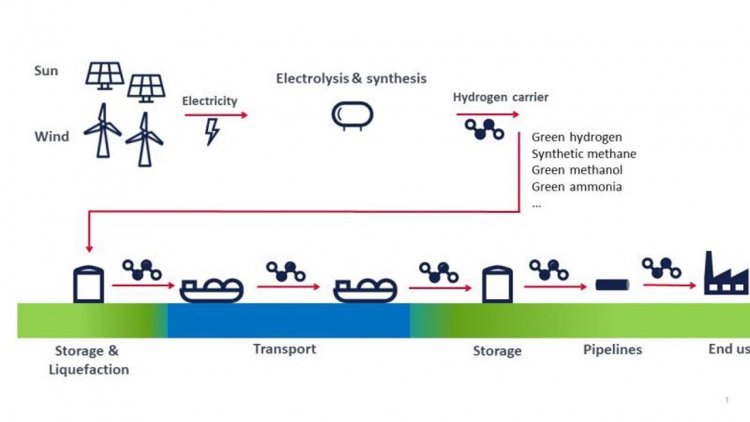

It is clear that solar and wind will be the renewable energy sources of the future. However, in Belgium and Western Europe, there is not enough wind or solar energy, while other regions in the world in fact have solar and wind energy in abundance. In order to achieve a reliable, affordable and sustainable energy system, local production of solar and wind energy will therefore have to be supplemented by the supply of some of the necessary renewable energy from abroad. Molecules can act as energy carriers to efficiently transport green energy through pipelines and ships. Hydrogen, as a carrier of renewable energy, plays an important role in the blend of end-user solutions.

Over a year ago, seven major industrial players and public stakeholders joined forces and expertise to jointly analyse the opportunities for importing green hydrogen into Belgium. The coalition, consisting of DEME, ENGIE, Exmar, Fluxys, Port of Antwerp, Port of Zeebrugge and WaterstofNet, has now completed a large-scale industrial study mapping out the financial, technical and regulatory aspects of the entire hydrogen import chain – from production abroad to delivery via ships and pipelines to Belgium and internal distribution – and providing a basis for the further roll-out to industrial applications.

After thorough analysis of all the elements, the study concludes that importing this form of renewable energy is a necessary and feasible solution to the growing shortage in Western Europe. Various types of hydrogen-derived carriers from a range of supply regions will be able to provide cost-competitive renewable energy and raw materials by 2030-2035. The most promising green energy carriers are ammonia, methanol and synthetic methane. These can be deployed through existing modes of transport – such as pipelines and maritime transport in particular – and growing markets, encouraging a rapid start.

According to the study published by the hydrogen import coalition, this import of renewable energy through green hydrogen carriers will therefore become an essential part of our energy supply, complementing the sustainable transition based on domestically generated energy. Belgium has maritime ports and extensive pipeline infrastructure, is linked to the major industrial clusters and has the capacity to meet its own energy needs and those of surrounding countries.

Now that the feasibility study has been completed, the coalition partners want to take some concrete next steps. They will analyse how to prepare the seaports to receive the hydrogen carriers of the future, seeking maximum synergy to serve its national interests. Specific pilot projects are being set up whereby they can make maximum use of the Flemish expertise and strength in the area of logistics, industry and technology for the development of a sustainable economy and the climate transition in our own region and a broader hinterland.

Alexander De Croo, Prime Minister of Belgium:

“Hydrogen will play a decisive role in the energy transition and in making our industry sustainable. This study provides essential new insights for the further roll-out of a hydrogen economy and the further reduction of CO2 emissions. The next step is to develop a long-term strategy for importing hydrogen.”

Jan Jambon, Prime Minister of the Flemish Government:

“Flanders is ideally positioned to play a pioneering role in the hydrogen economy at a European level. It has the energy hubs of Antwerp and Zeebrugge, it has transportation infrastructure, an extensive network of pipelines to those ports and to Germany, and technology companies operating in it.”

Jacques Vandermeiren, CEO at Port of Antwerp:

“We want to give hydrogen every chance as an energy carrier, a basic element for chemistry and a fuel, and are therefore committing ourselves as an active pioneer in the hydrogen economy. As a world port and Europe’s largest integrated chemical cluster, we are an important link in this chain. The outcome of this study and its next steps offer promising perspectives for a further large-scale roll-out of hydrogen applications.”

Annick De Ridder, Port Alderman:

“This study confirms that hydrogen can play a key role not only in making the port of Antwerp sustainable, but also in the rest of Europe. It is therefore crucial that, as a port of the future, we live up to our ambition and play a pioneering role in terms of sustainable solutions. Thanks to the collaboration between this coalition of partners with the right expertise and the government bodies involved, we have all the assets we need to take further concrete steps in this regard and to set an example for other ports and regions.”

Tom Hautekiet, CEO Port of Zeebrugge:

“As a multifunctional energy hub with a state-of-the-art LNG infrastructure, (i.e. storage capacity and pipelines), the port of Zeebrugge is ideally suited to receive the hydrogen carriers of the future. Together with the partners in this coalition, we wish to develop our role in projects concerning the import and export of hydrogen and participate in creating a hydrogen economy.”