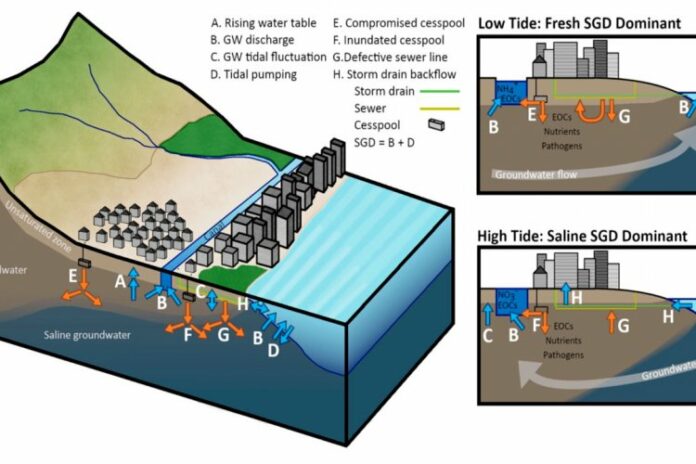

When people think of sea level rise, they usually think of coastal erosion. However, recent computer modeling studies indicate that coastal wastewater infrastructure, which includes sewer lines and cesspools, is likely to flood with groundwater as sea-level rises.

A new study, published by University of Hawai’i (UH) at Mānoa earth scientists, is the first to provide direct evidence that tidally-driven groundwater inundation of wastewater infrastructure is occurring today in urban Honolulu, Hawai’i. The study shows that higher ocean water levels are leading to wastewater entering storm drains and the coastal ocean—creating negative impacts to coastal water quality and ecological health.

The study was led by postdoctoral researcher Trista McKenzie and co-authored by UH Sea Grant coastal geologist Shellie Habel and Henrietta Dulai, advisor and associate professor in the UH Mānoa School of Ocean and Earth Science and Technology (SOEST). The team assessed coastal ocean water and storm drain water in low-lying areas during spring tides, which serve as an approximation of future sea levels.

To understand the connection between wastewater infrastructure, groundwater and the coastal ocean, the researchers used chemical tracers to detect groundwater discharge and wastewater present at each site. Radon is a naturally occurring gas that reliably indicates the presence of groundwater, while wastewater can be detected by measuring specific organic contaminants from human sources, such as caffeine and certain antibiotics.

McKenzie said:

“Our results confirm that indeed, both groundwater inundation and wastewater discharge to the coast and storm drains are occurring today and that it is tidally-influenced. While the results were predicted, I was surprised how prevalent the evidence for these processes and the scale of it.”

In low-lying inland areas, storm drains can overflow every spring tide. This study demonstrated that at the same time wastewater from compromised infrastructure also discharges into storm drains. During high tides, storm drains are becoming channels for untreated wastewater to flood streets and sidewalks. In addition to impeding traffic, including access by emergency vehicles, this flooding of contaminated water also poses a risk to human health.

The team also found evidence that many of the human-derived contaminants were in concentrations that pose a high risk to aquatic organisms. This has negative consequences to coastal organisms where the groundwater and storm drains discharge.

McKenzie said:

“Many people may think of sea-level rise as a future problem, but in fact, we are already seeing the effects today. Further, these threats to human health, ocean ecosystems and the wastewater infrastructure are expected to occur with even greater frequency and magnitude in the future.”

This project demonstrates that actions to mitigate the impact from sea-level rise to coastal wastewater infrastructure in Honolulu are no longer proactive but are instead critical to addressing current issues. Through its multi-partner effort, the Hawai’i State Climate Commission also raises awareness around the variety of impacts of sea level rise, including those highlighted by this study.

McKenzie said:

“Coastal municipalities should pursue mitigation strategies that account for increased connectivity between wastewater infrastructure and recreational and drinking water resources. We need to consider infrastructure that minimizes flooding opportunities and contact with contaminated water; and decreases the number of contaminant sources, such as installation of one-way valves for storm drains, decommissioning cesspools, monitoring defective sewer lines, and construction of raised walkways and streets.”