Bjørgulf Haukelidsæter Eidesen, CEO of Horisont Energi, said:

“The work carried out with our partner Haldor Topsøe A/S is pioneering and sets the global standard for blue hydrogen and ammonia plants, with an extremely low carbon footprint combined with industry-leading energy efficiency and compelling revenue potential. This is a clean ammonia plant at a scale that truly matters.”

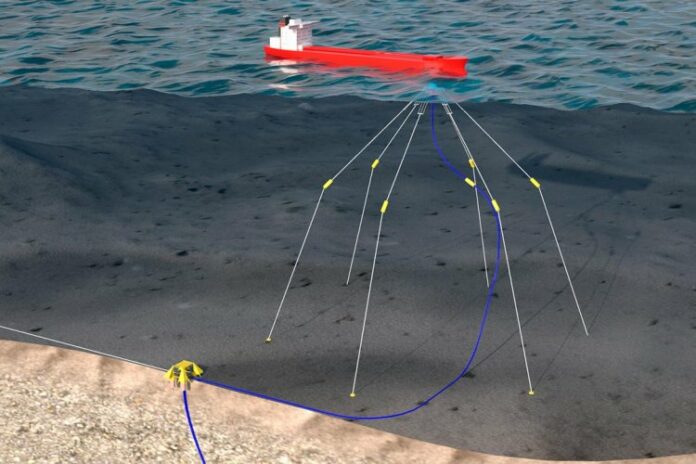

Through this first phase all the key aspects of the project have been addressed with the conclusion of feasibility. First off, a process design with a record low carbon footprint and an industry leading energy performance has been developed, secondly, feasible sites for the plant have been identified and studied together with Multiconsult, and the preferred site will soon be concluded and announced, a tie-in solution into Melkøya LNG has been identified and a formal study agreement has been entered into with the Snøhvit Unit, a feasible pipeline routing and design from Melkøya to the plant site has been developed, and finally an excellent quality carbon storage for the plant’s CO2 has been identified, namely Polaris. Together these elements form a solid basis for the continued development of the Barents Blue project in the next phase – the concept phase.

Horisont Energi will now award contracts for concept studies to various suppliers. This process will result in a concept decision, intended to be completed around the end of the year. Following this decision, detailed studies (front end engineering design – FEED) will lead to a final investment decision towards the end of 2022.

Due to the groundbreaking nature of the project, Norwegian state agency Enova has granted NOK 10 million for the concept study phase. In addition, Enova has shortlisted Horisont Energi as one of five candidate hydrogen projects in Norway for possible participation in the Important Projects of Common European Interest (IPCEI) on hydrogen.

Adding to the existing use of ammonia as input for fertilizer production and other industries, there is intense interest in the future use of ammonia as a fuel, either directly or by converting it into hydrogen. Horisont Energi is actively working with several potential customers for the clean ammonia in the European market.

Bjørgulf Haukelidsæter Eidesen, CEO of Horisont Energi, said:

“The Barents Blue project will be one of the largest ammonia plants in the world, providing climate-friendly and profitable market access for the natural gas reserves in the Barents Sea by tapping into the huge global ammonia market. The scale and potential of the project has led to substantial interest from a number of stakeholders, including the local community, NGOs and major companies in the energy business.”

The plant will deliver ultra-low carbon footprint, with between 99.3% and 99.9% overall CO2 capture. It will also have industry-leading energy efficiency. Based on circular economy principles, Horisont Energi will select recyclable and reusable materials, and consumables and chemicals of which the by-products can be reused in other industries.

Bjørgulf Haukelidsæter Eidesen, CEO of Horisont Energi, said:

“Our clear ambition is to make blue ammonia, which is produced from natural gas with carbon capture, just as environmentally friendly as plants based exclusively on renewable electricity and electrolysis, so-called green ammonia. In the future, it is also our intention to develop green ammonia facilities, but regardless of the technology, we aim to set the industry standard for large-scale clean ammonia production.”