Recoverable resources are estimated at between 1.3 and 3.6 million standard cubic metres of oil equivalent, corresponding to 8-23 million barrels of oil equivalent.

Rune Nedregaard, senior vice president, Exploration and Production South, says:

“This is the first Equinor-operated well in the production licence, and the fifth discovery on the Norwegian continental shelf this year. The discovery is in line with our roadmap of exploring near existing infrastructure in order to increase the commerciality.”

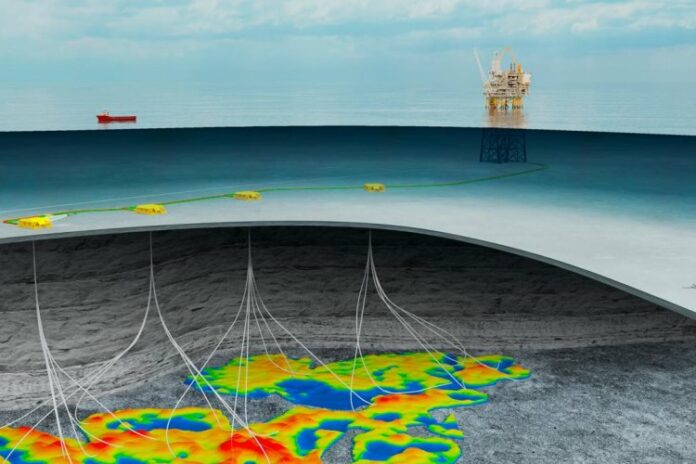

Exploration wells 34/6-5 S and 34/6-5 ST2 on the Garantiana West prospect were drilled some 10 kilometres north-east of the Visund field, and 120 kilometres west of Florø.

The primary exploration target for exploration well 34/6-5 S was to prove hydrocarbons in the Cook formation from the early Jurassic period. The secondary exploration target was to examine the hydrocarbon potential in the Nansen formation from the early Jurassic/late Triassic period.

Well 34/6-5 S encountered a total oil column of 86 metres in the Cook formation. An about 60-metre effective medium-good quality sandstone reservoir was found.

Exploration well 34/6-5 S also encountered sandstones in the Nansen formation, but the reservoir is auriferous, and the exploration target is classified as dry.

A successful formation test has been performed. The test indicates good flow qualities with stable flowing pressure and low pressure drop, in addition to consistent pressure build-up.

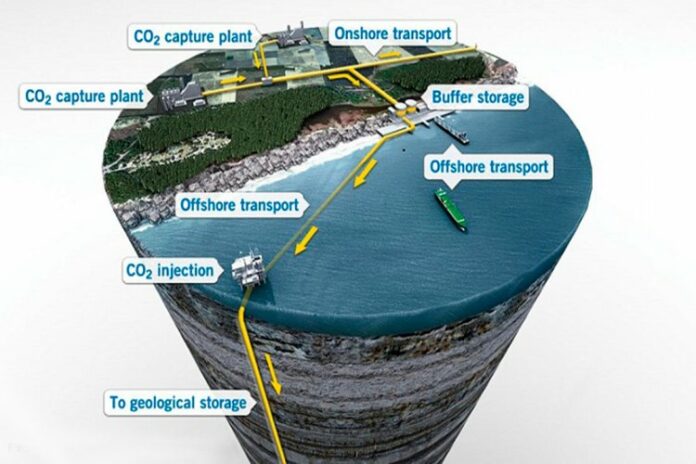

The licensees will consider tying in the discovery to the Garantiana field development project.

Due to technical problems in the main trajectory a technical side-step was made through well 34/6-5 ST2. The well was formation tested, and extensive data acquisition and sampling were carried out.

This is the fifth exploration well in production licence 554. The licence was awarded on 19.02.2010 in APA2009. The licensees are Equinor Energy AS, Vår Energi AS and Aker BP ASA.

Well 34/6-5 S was drilled to a vertical depth of 3952 metres below sea level and completed in the Nansen formation from the late Jurassic period. Well 34/6-5 ST2 was drilled to a vertical depth of 3750 metres below sea level, and completed in the upper part of the Amundsen formation. Drilled in 285 metres of water the wells have been permanently plugged and abandoned.

Well 34/6-5 S was drilled by the West Hercules drilling rig, which will now drill the pilot hole in production licences PL272 and 035 (near the discoveries 30/11-8 S (Krafla) and 30/11-9 S (Askja)) in the North Sea.