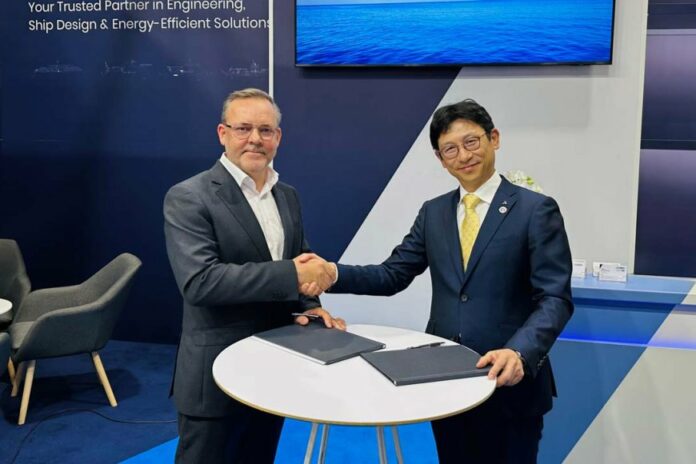

Google signed an agreement with the Chilean government during a meeting on Wednesday to deploy a 14,800-kilometer (9,196-mile) submarine data cable across the Pacific Ocean to connect with Australia and Asia, set to be operational by 2027.

The pact, the first of its kind between the technology giant and a country, aims to bolster Chile’s digital connectivity with Asian nations, including China, Chile’s largest trading partner, while advancing its ambitions to become a regional hub for Latin America.

“It’s the first submarine cable in the South Pacific, so it’s an important commitment in that we have an extraordinary strategic partner for a cable that should be operational in 2027,” Transport Minister Juan Carlos Muñoz told journalists.

Cristian Ramos, head of telecommunications infrastructure for Alphabet’s Latin American unit, said the cable would be open for use by other entities, including technology firms operating in Chile.

The initiative coincides with intensifying competition between China and the United States for influence in Latin America, with submarine cables emerging as crucial infrastructure in their technological rivalry.

While the total investment in the project remains undisclosed, Chilean officials had previously estimated costs ranging from $300 million to $550 million, with Chile contributing $25 million, according to Patricio Rey, general manager of Desarrollo Pais, a state-owned partner in the venture.

Authorities suggested the cable could enhance the performance of Asian platforms like TikTok, facilitate astronomical data transmission, and support mining operations in both Chile and Australia.

“Mining companies that have operations in Chile and Australia, by having a direct route, we can think about a shared command center… where the command centers can support each other,” said Deputy Secretary of Telecommunications Claudio Araya.

The cable, connecting Valparaiso in Chile’s central region to Australia, is scheduled for deployment next year. Chile’s state Desarrollo Pais is also looking into linking the cable to Argentina via a border crossing.

Partners aim to identify an operator to commercialize the cable’s capacity, though a selection may not be finalized before year-end.

Araya said the initiative could attract similar ventures to connect South America with Asia. Separately, Chile is planning a submarine cable to link the southern tip of South America with Antarctica, primarily for research purposes.

Source: Reuters