The hydrogen plant is part of H2Ports, a project led by the Valenciaport Foundation and the Valencia Port Authority.

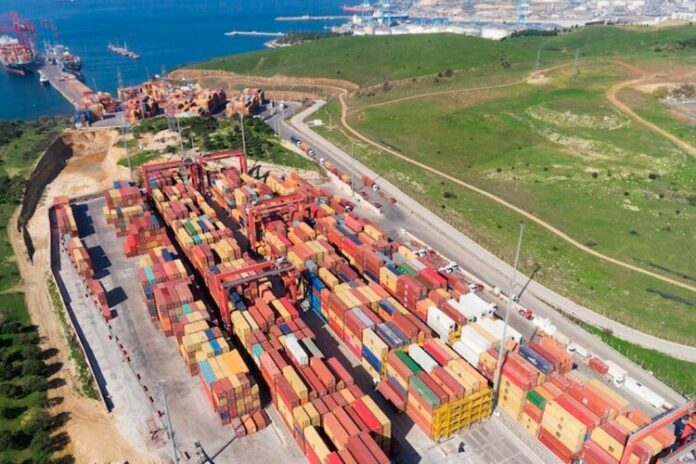

From January, the Port of Valencia will have a “hydrogen station” or green hydrogen supply station. The station will be mobile and will provide the necessary fuel, in the appropriate conditions and quantities to guarantee the continuous working cycles of the equipment forming part of the H2Ports project. The first of this equipment will be the machine or prototype of the Reach Stacker vehicle or “container stacker” which will be powered by this energy and which will be tested at MSC Terminal Valencia. The second piece of equipment to be serviced by the hydrogen plant will be a 4×4 tractor unit equipped with a fuel cell stack for testing in loading/unloading operations at Grimaldi Group’s Valencia Terminal Europa.

Federico Torres, the head of Ecological Transition of the APV, explains:

“These are very important machines in the Port of Valencia because they are in operation 24 hours a day, 365 days a year and within our objectives and calculations of emissions, the terminal machinery represents almost 25% of the emissions that we want to reduce through this type of energy.”

The hydrogen supply station (HRS) is being developed at the National Hydrogen Centre, and will include a fixed part that will be dedicated to receiving and storing hydrogen from an external supplier and compressing it to delivery pressure, and a mobile part that will store the compressed hydrogen and include a hydrogen dispenser for refuelling the port machinery. The HRS will consist of three main components: a low-pressure hydrogen tank into which the hydrogen supplier will discharge, a two-stage water-cooled piston hydrogen compressor with heat exchangers integrated into the system, and a mobile high-pressure hydrogen storage and supply unit, consisting of two hydrogen storage stages at 300 and 450 bar and a 350 bar dispenser for heavy vehicle with communications.

Aurelio Martínez, the president of the PAV, Aurelio Martínez, said:

“We are currently coordinating with the National Hydrogen Centre the location of this facility in the Port of Valencia. The work will begin in January, so once again we will be pioneering and taking a step forward with this type of infrastructure, in our commitment to sustainability”.

The European project that will enable Valencia and its port to work and move port machinery with hydrogen is called “H2PORTS – Implementing Fuel Cells and Hydrogen Technologies in Ports”. It is a development coordinated by the Valenciaport Foundation in close collaboration with the Port Authority, and is financed by the European Union’s Fuel Cell and Hydrogen Joint Undertaking (FCH JU) programme. Its main objective is to test and validate hydrogen technologies on port machinery to provide applicable and real solutions without affecting the performance and safety of port operations and producing zero local emissions.

The H2Ports project will involve a total investment of 4 million euros and involves, in addition to the Valenciaport Foundation and the Valencia Port Authority, the National Hydrogen Centre and the private companies MSC Terminal Valencia, Grimaldi Group, Hyster-Yale, Atena Distretto Alta Tecnologia Energia Ambiente, Ballard Power Systems Europe and Enagás.