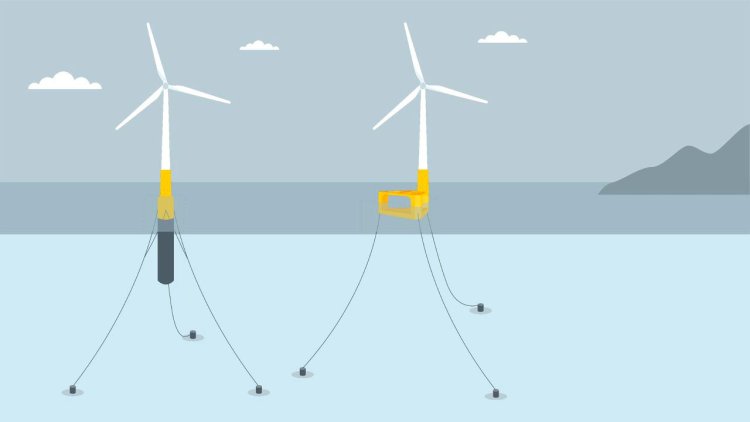

Having reaffirmed its commitment to Scotland earlier this year, the offshore energy company has now revealed its preferred floating wind foundation design for full-scale gigawatt (GW) commercial floating offshore wind, if successful in ScotWind. The Wind Semi, a semisubmersible wind turbine foundation, has been designed with flexibility, specifically to allow for fabrication and assembly based on local supply chain capabilities.

Sonja C. Indrebø, Equinor’s vice president of Floating Offshore Wind, says:

“We are ready to develop the next generation, large-scale commercial floating offshore wind in Scotland. By leveraging our twenty years of floating offshore wind experience and innovations, we plan to develop GW-size floating projects in one single phase. Implementing large scale projects will accelerate Scotland’s energy transition to net zero. At 1GW, this project would be over 30 times bigger than Hywind Scotland, the UK’s and Equinor’s first floating project and have the potential to not only position Scotland as a leader in deep water technology, but also create opportunities for both existing suppliers and new entrants to the offshore wind sector.”

To ensure that the technology can be deployed cost effectively whilst maximising local benefits, Equinor has developed a set of design principles and solutions that are applicable across floating concepts.

Equinor installed the first ever floating offshore wind turbine in 2009, and operates Hywind Scotland (30 MW), the world’s first floating wind farm. Since it began production in 2017, Hywind Scotland has consistently achieved a higher capacity factor than other UK wind farms, demonstrating the true potential of floating offshore wind.

Indrebø says:

“Hywind Scotland proved that the floating concept works, and as we move to the next generation floating offshore wind projects, we need to demonstrate that floating offshore wind is deployable at scale, in different geographies cost effectively whilst bringing local benefits. We have seen the journey of fixed bottom offshore wind, and combined with our long experience in floating, we can take learnings into account as we design and innovate the concepts for full-scale GW floating wind farms.”

The Wind Semi has several features making it particularly suited for harsh waters, and solutions that can maximise the opportunities for the Scottish supply chain:

- Increased dependability: By introducing a passive ballast system, the Wind Semi has a simple substructure design, reducing the risk of system failure and the amount of maintenance needed

- Simpler, more robust design: A flat plate design that is free from bracings, heave plates and complicated nodes that are prone to fatigue cracking

- Flexibility towards the supply chain: With a harbour draught of less than 10 m, the Wind Semi’s turbine integration can be assembled at most industrialised ports. The Wind Semi’s simpler flat plate design enables the substructure to be built in blocks that can either be fabricated locally and/or shipped from other locations.

Indrebø says:

“Scotland can be in the forefront of this exciting technology. We asked ourselves how we can achieve industrial standardisation and maximise local content opportunities to create additional and sustainable long-term value from floating offshore wind projects. With a design-based approach we’ve used our experience and gone right back to basics to incorporate this focus in the initial concept design.”

Equinor is technology agnostic and will select the best suited floating wind concept for its projects. Water depths, conditions around shipyards and ports, and the specialisations and capacity of the local supply chain are primary drivers for selecting a given design.

Selecting the most cost-efficient concept design and achieving optimal fabrication efficiency is key to competitive full-scale floating wind parks. In Scotland, Equinor will actively work to develop a broader and more competitive supply chain that can efficiently and effectively deliver a ScotWind floating projects safely, on time, and on budget. In particular, Equinor will work closely with the domestic supply chains in Scotland and rest of the UK to maximise the opportunities for local suppliers and local communities.