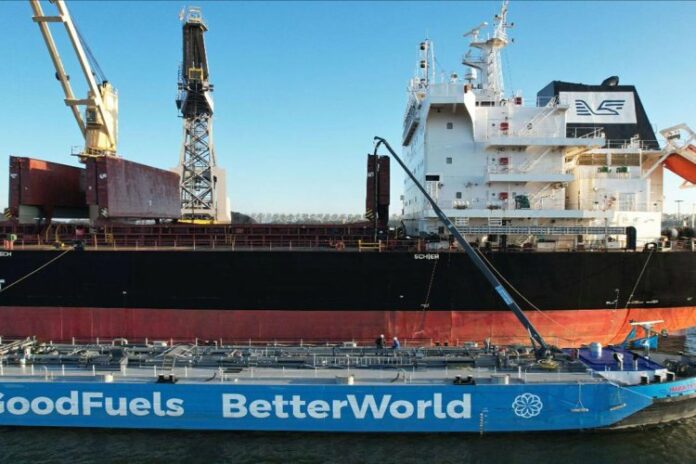

As part of Eagle Bulk Shipping’s ambitions to improve the environmental performance of its fleet, the 63,529 DWT bulk carrier Sydney Eagle was bunkered with GoodFuels’ advanced marine biofuel for the first time during its call at Terneuzen, the Netherlands. Eagle Bulk Shipping’s carbon footprint is substantially reduced when using GoodFuels’ sustainable marine biofuel, which enables an 80-90% well-to-exhaust CO2 reduction.

GoodFuels’ biofuels are produced from certified renewable feedstocks labelled as 100% waste or residue that cannot be used for any higher quality application or recycling, such as used cooking oil and waste animal fats. The biofuels “drop in” to tanks without any alterations to the fuel infrastructure or marine engines, and ensure compliance with the International Maritime Organization’s (IMO) Sulphur Cap as they are virtually free of all SOX emissions.

The maritime industry faces an urgent need to reduce its Greenhouse Gas emissions and commit to sustainable shipping. Owners and operators, such as Eagle Bulk Shipping, are already required to meet the 0.5% sulphur limit as enforced in January 2020, and recently adopted regulation will require ships to improve their energy efficiency, in line with the IMO’s target to reduce the average carbon intensity of shipping by at least 40% by 2030, and 70% by 2050.

Sustainable biofuels are a leading contender for marine decarbonisation due to their drop-in characteristics, well-tuned infrastructure, and ability to enable stakeholders to comply with current and imminent environmental legislation. They are also one of the few solutions that already exist on the market today and are available for all vessel types.

Isabel Welten, Chief Commercial Officer at GoodFuels, said:

“This announcement is the latest step in scaling our low-carbon biofuels for wider commercial use within the maritime industry. With our ambition to become the principal sustainable fuel supplier for the global transport industry, and our offer of mature 100% biofuels, GoodFuels is perfectly positioned to facilitate the energy transition for owners and operators.

“We hope more organisations will follow Eagle Bulk Shipping’s footsteps in embracing our credible near-zero carbon alternative to fossil fuels, as the industry steps up its efforts to meet its environmental regulatory targets in the near future.”