Russian sailors have evacuated the guided-missile cruiser Moskva, the flagship of its Black Sea fleet, after a fire that detonated ammunition aboard, Russian state media reported Wednesday.

State media outlets TASS and RIA, citing the Russian Defense Ministry, said the Moskva had been seriously damaged in the incident and that the cause of the fire was being investigated. The Russian reports gave no information on possible casualties.

But hours earlier, a Ukrainian official claimed the Russian warship had been hit by cruise missiles fired from Ukraine.

Due to large storms over the Black Sea obscuring satellite imagery and sensory satellite data, CNN has not been able to visually confirm the ship has been hit or its current status, but analysts noted that a fire on board such a ship can lead to a catastrophic explosion that could sink it.

Whatever the reason for the fire, the analysts say it strikes hard at the heart of the Russian navy as well as national pride, comparable to the US Navy losing a battleship during World War II or an aircraft carrier today.

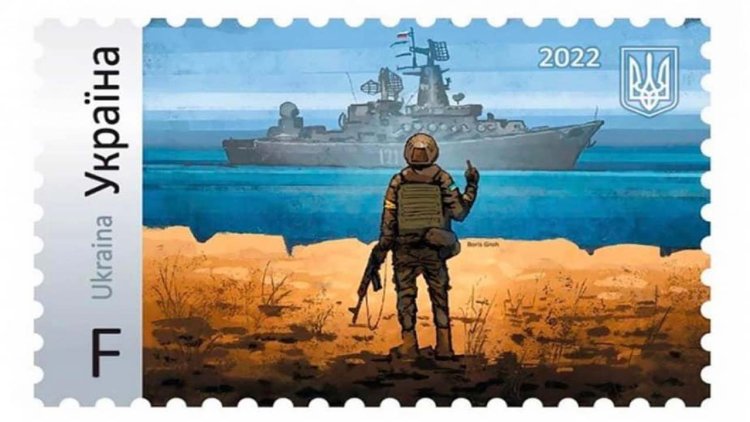

Photo: The Russian Navy cruiser Moskva, bottom, is seen in port in Sevastopol, Crimea, on April 7.

“Only the loss of a ballistic missile submarine or the Kutznetsov (Russia’s lone aircraft carrier) would inflict a more serious blow to Russian morale and the navy’s reputation with the Russian public,” said Carl Schuster, a retired US Navy captain and former director of operations at the US Pacific Command’s Joint Intelligence Center.

Alessio Patalano, professor of war and strategy at King’s College in London, said losing the warship would be a “massive blow” for Russia.

“Ships operate away from public attention and their activities are rarely the subject of news. But they are large floating pieces of national territory, and when you lose one, a flagship no less, the political and symbolic message — in addition to the military loss — stands out precisely because of it,” he said.

The 611-foot-long (186 meters) Moskva, with a crew of almost 500, is the pride of the Russian naval fleet in the Black Sea. Originally commissioned into the Soviet navy as the Slava in the 1980s, it was renamed Moskva in 1995 and after a refit reentered service in 1998, according to military site Naval-Technology.com.

The Moskva is armed with a range of anti-ship and anti-aircraft missiles as well as torpedoes and naval guns and close-in missile defense systems.

All those represent massive amounts of explosive ordnance in its ammunition magazines. Any fire nearing them would have given the crew limited options to deal with the threat, Schuster said.

“When a fire reaches your ammunition magazine(s), you have two choices; 1) flood them or 2) abandon ship,” Schuster said. “Otherwise your crew is onboard to be wiped out by the catastrophic explosion that follows a fire reaching several hundred tons of ordnance.”

Odesa state regional administrator Maxim Marchenko claimed in a post on Telegram that Ukrainian forces had used Neptune cruises missiles to attack the Moskva. If that’s true, the Moskva would potentially be the largest warship ever taken out of action by a missile, Schuster said.

Such an achievement would represent a big advance for Kyiv’s forces. The Neptune is a Ukrainian weapon, developed domestically based on the Soviet KH-35 cruise missile. It became operational in the Ukrainian forces just last year, according to Ukrainian media reports.

If it was used to attack the Moskva, it would be the first known use of the Neptune during the war, according to a post on the website of the Center for International Maritime Security (CIMSEC) from Lt. Cmdr. Jason Lancaster, a US Navy surface warfare officer.

His post for the CIMSEC on Tuesday said the threat posed by mobile shore-based cruise missiles like the Neptune “changes operational behavior” of an enemy.

Russian “ships will operate in ways to minimize the risk of detection and maximize their chances to defend themselves,” Lancaster wrote. “These behavioral changes limit Russia’s ability to utilize their fleet to their advantage. The added stress of sudden combat increases fatigue and can lead to mistakes.”

According to Patalano, the war professor: “It would appear the Russians have learned that the hard way today.”

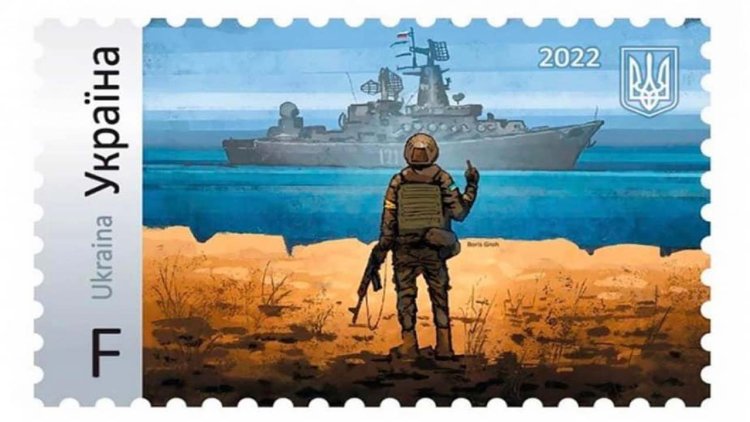

The Moskva also poses symbolic significance to Ukraine as it was one of the ships involved in the famous exchange at Snake Island in February, according to Oleksiy Arestovych, an adviser to Ukrainian President Volodymyr Zelensky.

According to a purported audio exchange in late February, as the Russians approached the Ukrainian garrison on Snake Island, also known as Zmiinyi Island, in the Black Sea, a Russian officer said: “This is a military warship. This is a Russian military warship. I suggest you lay down your weapons and surrender to avoid bloodshed and needless casualties. Otherwise, you will be bombed.”

A Ukrainian soldier responded: “Russian warship, go f*** yourself.”

Image: On April 12, 2022, Ukrposhta presented and put into circulation the first in martial law conditions postage stamps with a “Russian warship, go…!” slogan.

If the Moskva is lost, it would be the second large-sized Russian naval vessel to suffer that fate during Moscow’s war with Ukraine. In late March, Ukraine said a missile strike had destroyed a Russian landing ship at the port of Berdiansk.

Source: CNN