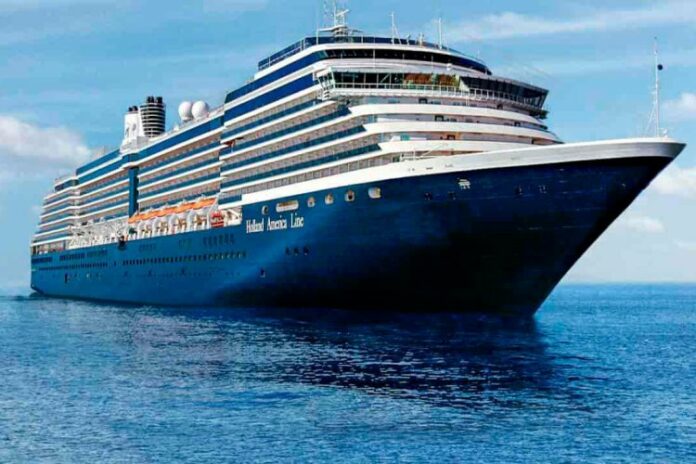

CNN has identified the vessel as the bulk carrier Matros Pozynich. On April 27, the ship weighed anchor off the coast of Crimea, and turned off its transponder. The next day it was seen at the port of Sevastopol, the main port in Crimea, according to photographs and satellite images.

The Matros Pozynich is one of three ships involved in the trade of stolen grain, according to open source research and Ukrainian officials.

Crimea, annexed by Russia in 2014, produces little wheat because of a lack of irrigation. But the Ukrainian regions to its north, occupied by Russian forces since early March, produce millions of tons of grain every year. Ukrainian officials say thousands of tons are now being trucked into Crimea.

Kateryna Yaresko, a journalist with the SeaKrime project of the Ukrainian online publication Myrotvorets, told CNN the project had noticed a sharp increase in grain exports from Sevastopol — to about 100,000 tons in both March and April.

From Sevastopol, according to satellite images and tracking data reviewed by CNN, the Matros Pozynich transited the Bosphorus and made its way to the Egyptian port of Alexandria. It was laden with nearly 30,000 tons of (Ukrainian) wheat, according to Ukrainian officials.

But the Ukrainians were one step ahead. Officials say Egypt was warned that the grain was stolen; the shipment was turned away. The Pozynich steamed towards the Lebanese capital, Beirut, with the same result.

The Matros Pozynich turned off its transponder again on May 5, but imagery from Tankertrackers.com and Maxar Technologies shows it traveled to the Syrian port of Latakia.

The Syrian regime has a close relationship with Russia and the Russian military are frequently in Latakia. Indeed, the Matros Pozynich is named after a Russian soldier killed in Syria in 2015.

Mikhail Voytenko, editor-in-chief of the Maritime Bulletin, told CNN that the grain could be reloaded onto another ship at Latakia to disguise its origins. “When the destination port starts to change without any serious reason, this is another proof of smuggling,” he said.

In its first comments on the illicit export of Ukrainian grain, the Defense Ministry’s Intelligence Directorate said Tuesday that “a significant part of the grain stolen from Ukraine is on vessels sailing under the Russian flag in the waters of the Mediterranean.”

“The most likely destination of the cargo is Syria. The grain can be smuggled from there to other countries of the Middle East,” it said.

Shipping data shows that the Matros Pozynich is one of three bulk carriers registered to a company called Crane Marine Contractor, based in Astrakhan, Russia. The company is not under international sanctions. CNN’s efforts to reach the company were unsuccessful.

Yaresko says that the SeaKrime project has identified the true owners of the three ships as one of 29 companies under the umbrella of a large Russian corporation, whose other entities were sanctioned by the United States soon after the Russian invasion.

The Ukrainian Defense Ministry estimates that at least 400,000 tons of grain has been stolen and taken out of Ukraine since Russia’s invasion.

Mykola Solsky, Ukraine’s minister of Agrarian Policy and Food, said this week it is “sent in an organized manner in the direction of Crimea. This is a big business that is supervised by people of the highest level.”

CNN reported last week that trucks with Crimean license plates pilfered 1,500 tons of grain from storage units in Kherson. In Zaporizhzhia, trucks bearing the white “Z” symbol of the Russian military were spotted transporting grain to Crimea after the city’s main grain elevator was completely emptied.

This week, Ukrainian authorities reported more grain thefts by occupying forces. The Intelligence Directorate said that in one part of Zaporizhzhia, grain and sunflower seeds in storage were being prepared for transport to Russia. A column of Russian trucks carrying grain had left the town of Enerhodar — also in Zaporizhzhia — under the guard of the Russian military, the Directorate claimed.

While Russian ships are apparently able to carry Ukrainian grain on the high seas, Ukrainian farmers are finding it much more difficult to export their produce. Much of it would normally be shipped out of Odesa. While still in Ukrainian hands, Odesa has come under frequent missile attacks and much of the Black Sea is off-limits to merchant shipping.

Ukrainian shippers have diverted some grain via rail to Romania, as CNN reported last week. But it’s hardly a solution to what is becoming a supply crisis already having an impact on world markets.

Source: CNN