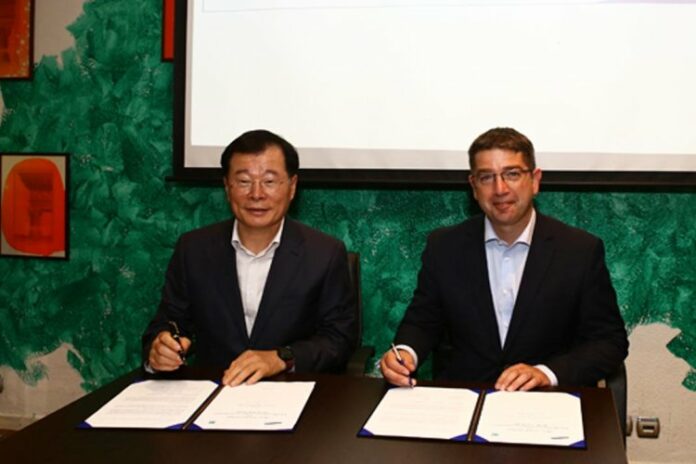

LR has granted Software Conformity Certification to Samsung Heavy Industries (SHI) for its electronic data recording and management solution, SVESSEL® eLogbook system, a key result of a Joint Development Project (JDP) formed earlier this year.

This is the first time SHI has been awarded classification society approval for its digitalised electronic logbook software application.

As part of the JDP, SHI created an electronic data recording and management solution that replaces the existing paper navigation log. By automatically entering the data of the voyage log in conjunction with the SVESSEL® BIG solution, the reliability of the data is enhanced.

The SVESSEL® eLogbook software was assembled based on IMO MARPOL Annexes and the IMO Technical Code on Control of Emission of Nitrogen Oxides from Marine Diesel Engines (NOx Technical Code) and was developed by the marine research institute of SHI. The purpose of the eLogbook is based on the ship condition database, logbook management database and other management functions.

This solution will also reduce the workload of crew members by simplifying and automating complex and repetitive voyage log jobs. By transforming existing onboard documents into digital documents using SVESSEL® eLogbook, SHI plan to not only reduce the crew of smart ships, but also build a foundation for autonomous navigation.

As the only classification society involved in the project, LR’s role was to deliver assurance on the correctness, safety and performance of SHI’s digitalised software technology. To do this, LR experts conducted a Software Conformity Assessment, which consisted of a developer capability assessment and an evaluation of SHI’s systems engineering approach, including its software engineering practices relevant to the development and sustainment of a digitalised electronic logbook. This led to the Software Conformity Certification being awarded.

Nick Brown, LR Group CEO, said:

“This is a significant step in our industry’s journey towards digitalisation and we are honoured to support Samsung Heavy Industries with its digital ambitions as it helps shipowners and operators optimise efficiencies, costs and safety with digital solutions.”

Jin-Taek Jung, SHI’s President & CEO said:

“It is hoped that SHI’s SVESSEL® eLogbook can replace the current paper document system in use onboard ships and realize more efficient and precise operation of ships. The eLogbook can reduce the routine works of crews in generating lots of documents, and also more importantly precise digital data can be shared between crews onboard and management offices onshore. The strength of our eLogbook comes from the combined solution with the digital data platform SVESSEL® through automatic filling of data. This is a start to unify all the precise information onboard in a digital form for the next step towards a remote controlled/unmanned ship. The hard works by the expertise in LR and SHI are highly appreciated for this project.”