Ørsted and WWF have deployed 12 3D-printed reef structures on the seabed between the wind turbines at Anholt Offshore Wind Farm in the Kattegat, which is part of the Greater North Sea ecosystem.

Among other things, overfishing, increasing oxygen depletion, and habitat loss have resulted in a decline of the cod stock in the Kattegat for the past 20 years. It is now alarmingly low. This creates a negative domino effect in the Kattegat ecosystem, impacting biodiversity and the marine ecosystem’s resilience against climate-driven changes.

The two partners behind the project hope that it will have positive effects on the Kattegat cod stock and in turn contribute to a healthier, more resilient marine ecosystem with improved biodiversity.

Filip Engel, Vice President of Sustainability at Ørsted, said:

”The ocean holds vast potential to help meet our climate goals. Improving ocean health and restoring marine biodiversity is fundamental to addressing biodiversity loss and the climate crisis. As governments around the world are ramping up ambitious plans to grow renewable energy capacity, offshore wind will take up more space.”

Bo Øksnebjerg, Secretary General, WWF Denmark, said:

”Marine biodiversity in Denmark is under heavy pressure, and today there are 90 % fewer cod in the Kattegat than in 1990. Action is needed – and urgently. We must give nature and wildlife a hand, while trying to solve our climate crisis by expanding our renewable energy production at the same time. To solve the nature crisis, we must leave nature in better shape than before.”

In recent decades, attention has been drawn to the fact that the extensive overconsumption of marine resources has had enormous consequences. Globally, these consequences include dwindling fish stocks, oxygen depletion near the seabed, and a loss of habitats for marine life, such as massive reduction of eelgrass meadows.

Cod is an important top predator, meaning it preys on other marine species and thereby contributes greatly to maintaining the balance in the marine ecosystem. When cod gets greatly reduced in numbers, the abundance of their prey – such as the green crab – will grow. As a result, seagrasses decline because the crabs eat both the seeds of the eelgrass and many of the snails that themselves keep the eelgrass free from being overgrown with algae.

This is a problem, as eelgrass is itself of great importance for both biodiversity and the climate. It provides important habitats for marine life, such as juvenile fish, it produces oxygen, and it stabilises the seabed. Crucially, eelgrass also very effectively stores carbon in its root network, preventing it from ending up in the atmosphere and contributing to the global temperature rise.

Last year, WWF Denmark and Ørsted installed biohuts at the piers in the port of Grenaa in collaboration with the Port of Grenaa and the Kattegat Centre. Together, the two projects offer new habitats for cod at key stages in their life cycle.

Biohuts can be described as fish kindergartens as they provide vital protection to small fish. Here, e.g. juvenile cod can seek shelter and food until they are large enough to swim out into deeper water.

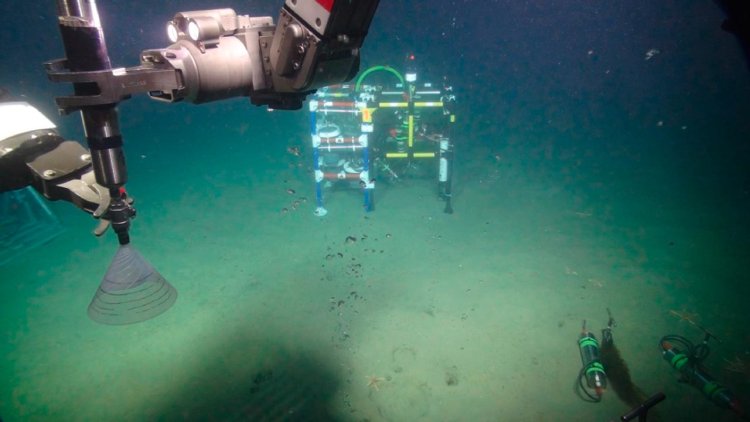

The 3D-printed reefs look like a wedding cake consisting of several levels that are connected to each other by hollows where fish can swim in and out of hiding places. At the same time, the structures themselves will provide surfaces and crevices where other organisms can attach. The reefs are about one cubic meter big and vary in width and weight to best imitate natural habitats and weigh up to half a ton.

Ørsted has seen how the boulder reefs that the company established when constructing the Anholt Offshore Wind Farm have become attractive oases for other marine species on an otherwise barren seabed. The expectation is that the new 3D-printed reefs can complement the stone reefs and will quickly become inhabited with life. WWF already has experience with 3D-printed reefs from a project in the Dutch part of the North Sea.

The project at Anholt Offshore Wind Farm is supported by PensionDanmark and PKA A/S which have a 30 % and 20 % share in the wind farm, respectively.

Facts about 3D-printed reefs

- The reefs are made from 70 % sand and 30 % pozzolanic cement made from volcanic ash and portland cement. These are natural materials and will not be harmful to the surrounding environment, even if parts of the reefs should erode over time.

- The 3D-printed reefs are biocompatible due to the absence of synthetic or toxic substances of industrial origin and the moderately basic pH of the structures at around 8.5-9.

- Each reef weighs between 200 and 550 kg.

- They are 1 m3 in size with a height of 1 m.

- The 3D-printed reefs are designed and developed based on a collaboration between WWF Netherlands and Reef Design Lab. The reef structures are produced by the Italian company D-Shape.