Six fixed offshore wind projects, with the potential to generate renewable electricity for more than 7 million homes, have been given the green light by the Secretary of State for Business, Energy and Industrial Strategy (BEIS) to enter into an Agreement for Lease with The Crown Estate.

In April, following the completion of a Habitats Regulations Assessment – an assessment of the potential impacts on the most valuable environmental habitats in the UK – The Crown Estate gave notice to the UK and Welsh Governments of its intent to proceed with the Offshore Wind Leasing Round 4 plan on the basis of a ‘derogation’.

The Secretary of State for Business, Energy and Industrial Strategy has now provided agreement that The Crown Estate can proceed with the plan, and the Welsh Government has not raised any objections to the notice.

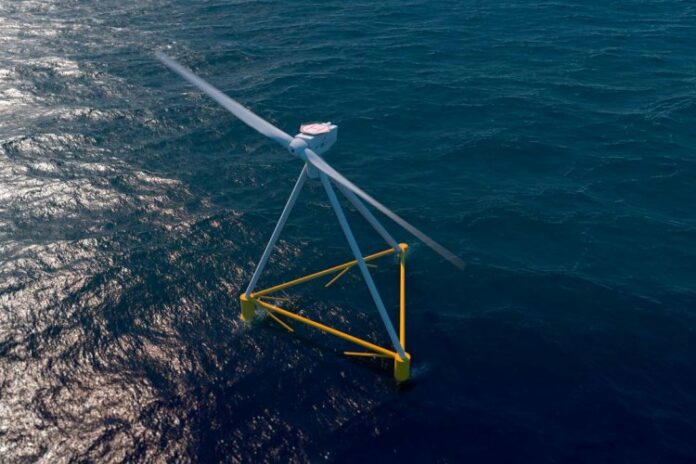

The move marks a significant moment in the UK’s response to climate change. From the first leasing round in 2001, The Crown Estate has supported the development of a world-class offshore wind market, which has grown to become the largest source of renewable electricity in the UK. On 5 July, The Crown Estate also announced plans to develop floating, as opposed to fixed, offshore wind farms in the Celtic Sea, which could bring up to 4GW of additional capacity.

As the climate emergency intensifies and demand for offshore wind accelerates, today’s agreement has the potential to make a critical contribution to delivering sustainable, renewable energy for the UK’s net zero future.

Dan Labbad, CEO of The Crown Estate said:

“It is the result of a tremendous collective effort from industry, environmental and conservation stakeholders, governments, and technical experts who have helped shape a rigorous and evidence-led outcome. In convening this broad range of stakeholders, we have been able to take a more informed and strategic approach to environmental compensation than ever before, ensuring we balance our rich biodiversity with the urgent need to progress vital renewable infrastructure.

“As we continue to harness the benefits of UK offshore wind, we remain firmly committed to collaborating with these organisations to build knowledge and evidence to help us understand how the increasingly busy marine environment can continue to thrive and support the wide variety of ecosystems and industries which rely on it.”

Business and Energy Secretary the Rt Hon Kwasi Kwarteng MP said:

“This month saw the price of offshore wind fall to record lows and today’s announcement will take us another step closer to increasing current levels of capacity almost five-fold by 2030.

“We are already a world leader in offshore wind and these new sites will help secure more clean, affordable, homegrown power for millions of households across the country, while reducing their reliance on costly fossil fuels.”

Welsh Government Minister for Climate Change, Julie James MS, said:

“As the first country in the world to declare a climate emergency, we welcome our partnership with The Crown Estate to deliver renewable energy projects here in Wales.

“We want to harness the power of our natural resources to benefit our communities, through projects that invest in local supply chains and green, skilled jobs.”