Keppel Offshore & Marine (Keppel O&M)’s wholly owned subsidiary, Keppel Shipyard, has won an international tender from Brazil’s National Oil Company, Petroleo Brasileiro S.A (Petrobras), for the engineering, procurement and construction (EPC) of P-80, a Floating Production, Storage and Offloading vessel (FPSO) for about US$2.9b.

Scheduled for completion in 1H 2026, the P-80 is the second FPSO that Keppel O&M will be building for Petrobras for the Buzios field in Brazil. The first FPSO, P-78, is currently under construction by Keppel Shipyard. The P-80 is structured on progressive milestone payments and will be cash-flow neutral during its execution lifecycle. It would add over S$4bn to Keppel O&M’s orderbook.

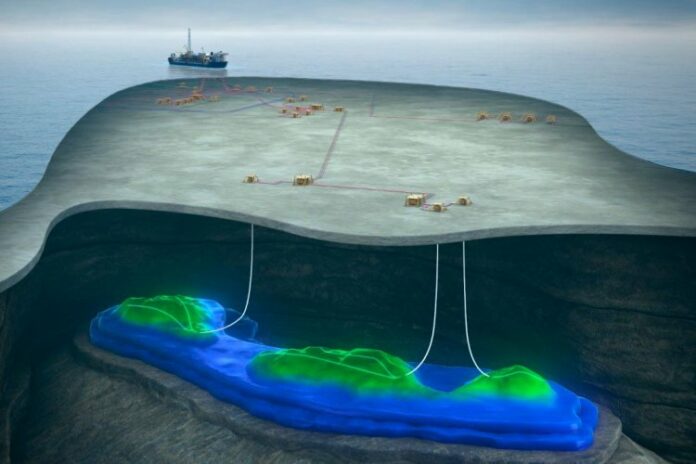

The P-80 will be one of the largest floating production units in the world with a production capacity of 225,000 barrels of oil per day (bopd), water injection capacity of 250,000 bpd, 12 million cubic metres of (Sm3/d) of gas processing per day and a storage capacity of two million barrels of oil. When completed, the P-80 will be on par with the largest oil producing platforms in Brazil.

Mr Chris Ong, CEO of Keppel O&M, said:

“By leveraging our strong EPC capabilities and network of yards, as well as teaming up with leading industry specialists, we have been able to offer a win-win solution that is both cost effective for our customer and profitable for Keppel O&M and our partners.

“Our first such project for the Buzios field, the P-78, is being built on this operating model. It is progressing on track with its schedule and within budget, and has been contributing to Keppel O&M’s earnings. Drawing from our experience with the P-78, we are confident that we can further enhance the efficiency and economics of the P-80, as well as generate a substantial amount of work in Brazil with thousands of jobs for the country.”

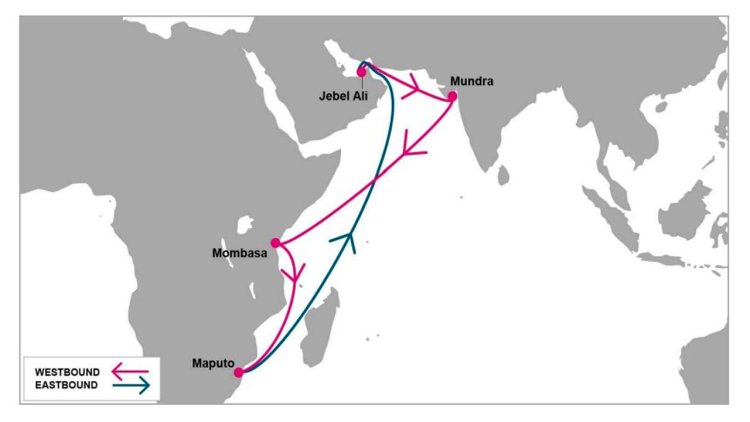

Keppel O&M will harness its global network of yards, offices and partners to undertake the project execution. The design and engineering will be carried out through its centres in Singapore, Brazil, China and India. The fabrication of the topside modules which weigh about 47,000 metric tonnes (MT) in total will be spread across its facilities in Singapore, China and Brazil, with the integration and commissioning works to be completed in Singapore. Construction of the hull and accommodation will be carried out by CIMC Raffles in China. Keppel O&M will also undertake the final phase of offshore commissioning works when the FPSO arrives at the Buzios field.

Petrobras operates the world’s largest carbon capture, utilisation and storage (CCUS) programme. The P-80, along with the P-78 FPSO, will incorporate green features such as carbon capture and reinjection of carbon back into the reservoir where it is stored. Both FPSOs are designed to maximise carbon reinjection and minimise the need for gas flaring.

In addition to CCUS, the P-80 will also be outfitted with energy recovery systems for thermal energy, waste heat and gas, as well as seawater deaeration to reduce the consumption of fuel and the carbon emissions of the vessel.

Mr Ong added:

“As a leader in providing sustainable offshore energy and infrastructure assets, Keppel O&M is glad to be able to support Petrobras in reducing the carbon emissions of the P-80 and P-78. Our partnership with Petrobras in their decarbonisation journey over the years includes work on four other FPSO projects, which showcase various innovative sustainability features, and we look forward to build on our strong track record of delivering high quality vessels to them.”

Keppel O&M has delivered a significant number of projects for Brazil and Petrobras over the years, which includes FPSOs, production platforms, Floating Storage Regasification Units, drilling rigs and accommodation vessels, to support Brazil’s energy infrastructure. BrasFELS, Keppel O&M’s yard in Angra dos Reis, Brazil is currently also undertaking integration and fabrication work for two other FPSOs that will operate in the Sepia field and the Buzios field.

The above contract is not expected to have a material impact on the net tangible assets or earnings per share of Keppel Corporation Limited for the current financial year.