U.S. shipping and logistics company Crowley has awarded Singapore-based Eastern Pacific Shipping (EPS) a contract for the charter of four newbuild containerships powered by liquified natural gas (LNG) for Crowley’s U.S.-Central America trade.

Using LNG significantly lowers vessel greenhouse gas emissions, such as sulfur oxide, carbon dioxide and nitrogen oxide while eliminating particulate matter compared with conventional diesel fuel. In addition, these vessels will be fitted with high-pressure ME-GI engines from MAN Energy Solutions, reducing methane slippage to negligible levels and making these vessels the most environmentally efficient in their category.

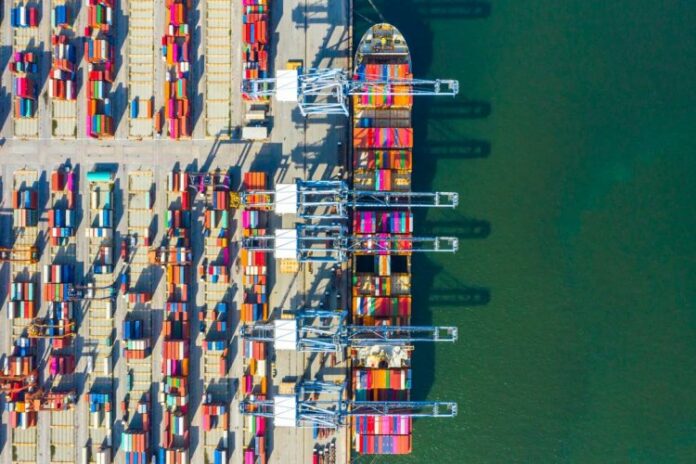

Each vessel, which will have capacity for 1,400 TEUs (20-foot container equivalent units), will feature 300 refrigerated unit plugs to reliably transport perishable cargo. Operating under a long-term time charter to Crowley, the ships will expand Crowley’s fleet and supply chain capabilities connecting U.S. markets to Nicaragua, Honduras, Guatemala and El Salvador.

EPS CEO Cyril Ducau said:

“We are excited to develop our U.S. market footprint through these long-term time charters with such a reputable partner. Like EPS, Crowley enjoys a rich history and diverse business portfolio, but more importantly, their organization is driven by a vision to lead the industry’s decarbonization efforts. Once delivered, these vessels will be IMO 2030 compliant five years ahead of schedule and will play an important role as the world and industry transition to cleaner energy sources.”

Tom Crowley, company chairman and CEO, said:

“These four ships will play a significant part in driving Crowley’s strategic growth in our supply chain services for the U.S., Central America and Caribbean. In addition, the vessels use of LNG and emissions technology will advance the company’s commitment to innovation and decarbonization in the shipping industry as part of our sustainability strategy. As more companies diversify their supply chains using nearshoring and the resources of Central America, Crowley will enhance our end-to-end logistics services to be partners in their growth.”

The vessels will be built by Korea’s Hyundai Mipo Dockyard and are slated for delivery in 2025.