Huisman has announced another contract award from COSCO Shipping (Qidong) Offshore Co., Ltd. for the design and construction of a 3,000+mt Leg Encircling Crane (LEC).

This crane will be installed on the second new build F-class jack-up vessel of Cadeler A/S, a key supplier within the offshore wind industry for installation services, operations and maintenance works.

The contract award follows this year’s order of a similar crane for Cadeler’s first F-class vessel. The F-class vessels feature a unique hybrid design, allowing them to convert from a foundation installation unit to a wind turbine generator installation vessel within a short period of time.

In 2021, Huisman received an order for two similar 2,600mt LECs for Cadeler’s X-class vessels, which are currently under construction at Huisman China. The X-class as well as the F-class vessels have a fully electric 40mt Huisman Pedestal Mounted Crane on board that functions as auxiliary crane.

With the LECs, Cadeler will be capable of installing foundations and wind turbines for next generation offshore wind projects worldwide.

Mikkel Gleerup, CEO of Cadeler A/S:

“Cadeler’s growth journey is dependent on stable and reliable suppliers, which we can trust not only to construct the required parts but also come up with visionary designs that meet future demands. Based on our previous experience from working together with Huisman on the cranes for the two new X-class vessels, we are confident that also this time around they will be able to deliver the high-quality cranes we need for our new F-class vessels, which will be able to lift the next generation of turbines and foundations.”

Huisman has designed its LECs to meet the requirements of the continually developing offshore renewables sector. The cranes are lightweight yet robust, have high positioning accuracy and are highly energy efficient, contributing to a reduced emissions footprint during the installation of increasingly large turbines.

David Roodenburg, CEO of Huisman:

“We are very thankful for the confidence that Cadeler has put in Huisman by awarding this fourth Leg Encircling Crane order. The trust of Cadeler’s clients is reflected in the long-term relationship that it has built with its supply chain. We admire the way Cadeler continues to motivate and challenge us to push boundaries on every project. Together with COSCO and other partners, we are committed to successfully delivering this project and enabling Cadeler to accelerate the installation of offshore wind capacity around the world.”

The crane will be built at Huisman’s production facility in Zhangzhou, China and is scheduled to be delivered end of 2025. The crane will be commissioned in 2026 at COSCO’s shipyard in Qidong, China, where both F-class vessels will be built.

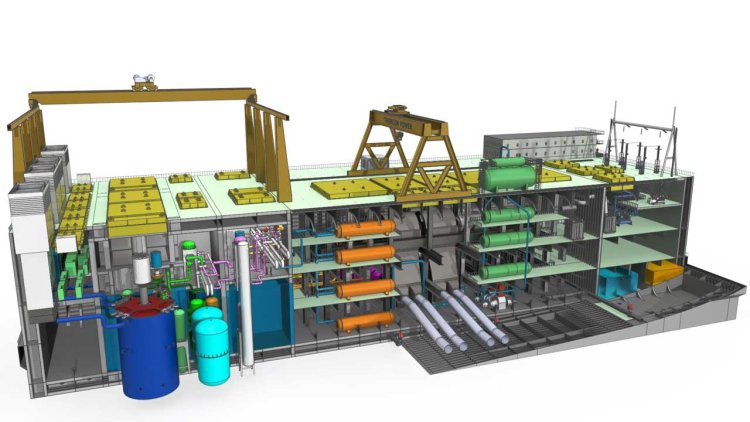

Features & benefits of the Huisman Leg Encircling Crane

- A fully electrically driven system, resulting in high positioning accuracy, reduced maintenance and high reliability.

- The optimised energy grid reduces the energy consumption of the crane significantly.

- In-house developed slew bearing system, providing highly reliable and accurate positioning of the crane.

- The boom’s unique design makes it stiff and lighter in weight.

- Stiff construction of the boom leading to reduced motion at the crane tip.

- Small tail swing allowing for optimised utilisation of free deck space.