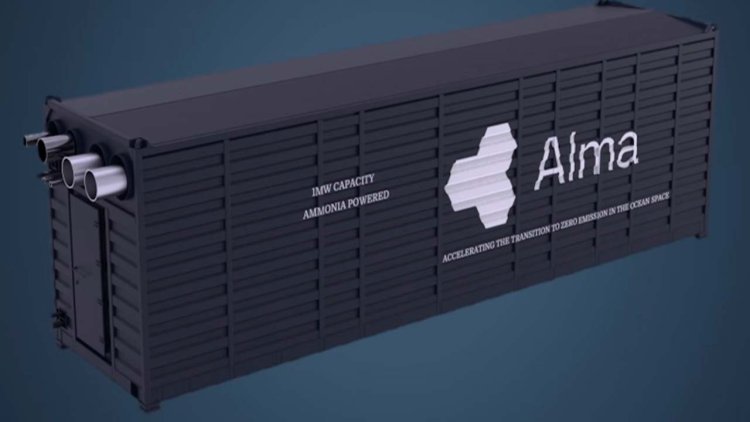

Alma Clean Power announces the achievement of a key milestone towards the development of a marine solid oxide fuel cell (SOFC) system. The company’s design of a 1 MW ammonia fuelled SOFC system received Approval in Principle (AiP) from DNV.

The SOFC system design has been evaluated for compliance with DNV class rules and IMO guidelines for fuel cell installations. The AiP is granted for a containerized module that includes safety systems to handle ammonia as fuel.

Bernt Skeie, CEO in Alma Clean Power, says:

“We’re excited that our design has received approval according to the highest standards in the maritime industry. Excellent collaboration with DNV as a leading class society within fuel cell systems and new fuels, has been key to get this far, and we look forward to continued collaboration as we move to the next phases of the project.”

Fuel cells have great potential to contribute to the achievement of the IMO goals for decarbonization of shipping, mainly because of their high efficiency and capability to run on hydrogen-based fuels.

Alma Clean Power’s fuel flexible SOFC systems can achieve more than 60% efficiency with low or zero emissions, depending on the fuel type. Compared to combustion engines, fuel cells do not have any fuel slip or require any blending with carbon-based fuels which would increase emissions.

Erling Johannessen, Senior Advisor in Alma Clean Power, says:

“Our fuel cell systems are designed to operate on a variety of low and zero emission fuels such as ammonia, LNG, LPG, hydrogen, methanol, syngas and LOHC (Liquid Organic Hydrogen Carriers). The AiP is therefore an important verification of key safety principles relevant for all fuel types.”

Two modules of the AiP approved SOFC system will be retrofitted as a 2 MW open-deck installation on the offshore supply vessel Viking Energy, as part of the EU-funded ShipFC project. The vessel is owned and operated by Eidesvik, and on contract for Equinor. The SOFC system will be integrated with existing dual fuel gensets and a battery pack, allowing the vessel to sail solely on emission-free, green ammonia for all dynamic positioning operations. The ammonia fuel cell system for ShipFC will be fully tested at the Energy House at Stord in Norway before installation onboard Viking Energy. This will be the first time an ammonia-powered fuel cell system is installed on commercially operative vessel.