The Ministry of Petroleum and Energy (MPE) gave the NPD the assignment to assess the resource potential of seabed minerals when the opening process for mineral activity started in 2020.

The MPE is responsible for stewardship of seabed minerals, and is leading the work on the opening process. The report is included as part of the opening process for seabed minerals.

“The NPD has built up expertise over many years, in part through a number of expeditions. We’ve mapped relevant areas, collected data and taken large volumes of mineral samples”, comments Kjersti Dahle, Director, Technology, Analysis and Coexistence.

“In this resource assessment, we’ve estimated how much of the various minerals might be found on the seabed in the studied area. Going forward, we will continue to reinforce the source data and the way we evaluate these resources”.

The transition to a low-emission society enhances the need for specific elements. These elements occur, for example, in deposits on the seabed. They are important raw materials in the energy transition, and they are in demand in relation to industry.

Dahle points out that technology development, together with more and better data, will yield even better understanding of the resource potential.

“The volume of recoverable resources depends on technology and economy. It remains to be seen whether the areas will be opened, and whether production can be profitable from a financial standpoint”.

Collecting, managing and making data from the Norwegian shelf accessible is one of the NPD’s most important tasks.

Since 2011, the NPD has collected data in the deepwater areas in the Norwegian Sea and the Greenland Sea in cooperation with the University of Bergen (UiB). The University of Tromsø (UiT) has also been included since 2020.

During the period from 2018-2021, the NPD itself conducted four expeditions to collect high-resolution seabed data over the most interesting mineral deposits; drilling operations and collection of mineral samples were also carried out.

Data from these expeditions, supplemented with data from scientific institutions, form the basis for this resource assessment.

“We have extensive experience in mapping the subsurface and assessing petroleum resources. I’m glad that we, with the expertise we bring, can also contribute to identifying resources that could be important in the energy transition”, says Dahle.

There are three types of mineral deposits on the seabed; manganese nodules, manganese crusts and sulphides. All three types contain multiple metals, and they are located at significant sea depths, mainly between 1500 and 6000 metres. On the Norwegian shelf, manganese crusts and sulphides have been found at depths around 3000 metres.

The NPD’s resource assessment for seabed minerals provides estimates of the resources in place; in other words, resources that have been proven, or that are expected to be present.

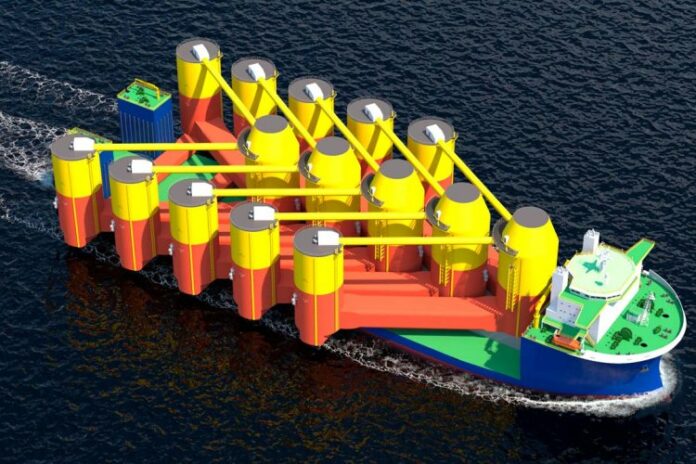

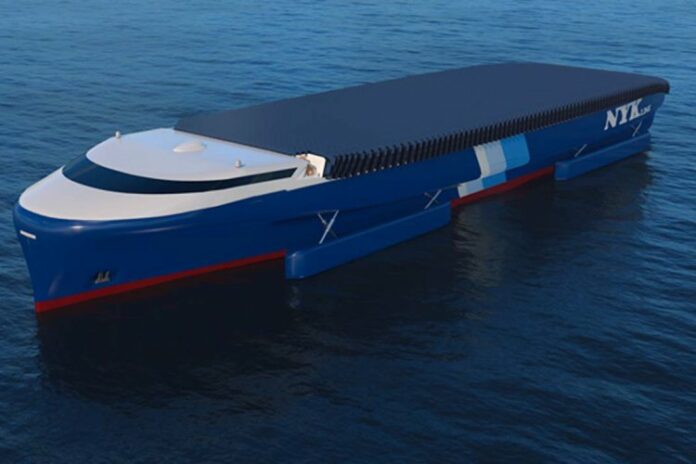

To confirm whether the mineral resources are recoverable, and can be recovered with acceptable environmental impact, this will require further investigation of the seabed and technological development surrounding recovering methods.

Several international organisations, such as the IEA and IRENA, are pointing to the significant and growing need for metals. As recently as in in 2020, the European Commission prepared an overview of critical input goods for the Union.

“Of the metals found on the seabed in the study area, magnesium, niobium, cobalt and rare earth minerals are found on the European Commission’s list of critical minerals. Costly, rare minerals such as neodymium and dysprosium are extremely important for magnets in wind turbines and the engines in electric vehicles”, says Dahle.