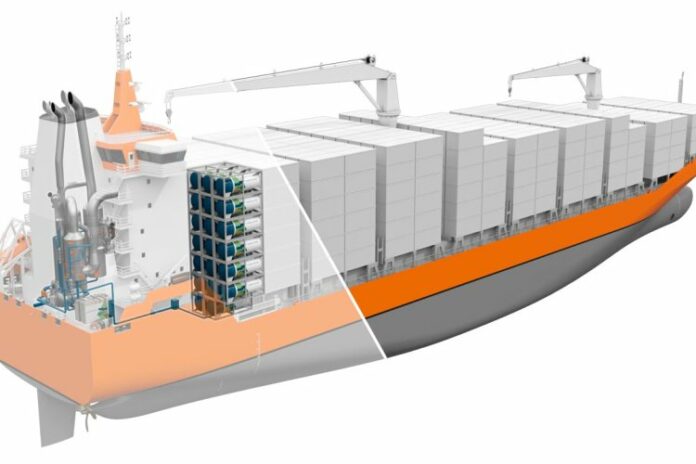

Design and engineering consultancy, Houlder, will participate in the ‘Winds of Change’ project led by Smart Green Shipping (SGS). The project will see an SGS FastRig wing sail retrofitted to a large vessel.

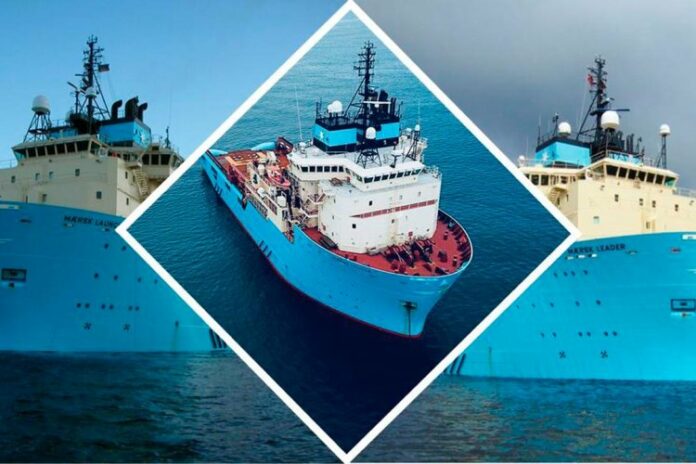

The project recently received funding from the UK Department for Transport as part of the Clean Maritime Demonstration Competition Round 3 (CMDC3) – delivered in partnership with Innovate UK. The collaboration involves the University of Southampton, SGS, Humphreys Yacht Design, Houlder, Malin Group, Caley Ocean Systems, Argo Engineering, Lloyd’s Register, MOL DryBulk and Drax. It will run from April 2023 to 2025.

Houlder’s role will span engineering system integration and vessel performance monitoring. Houlder will initially complete a vessel survey and then study the integration feasibility of the FastRig on the ship, identifying any safety risks and ensuring that regulatory and class society technical requirements are addressed in full. It will further develop the concept design for the integration of the FastRig, before working closely with Malin Group and Caley Ocean Systems on the installation and vessel modifications required.

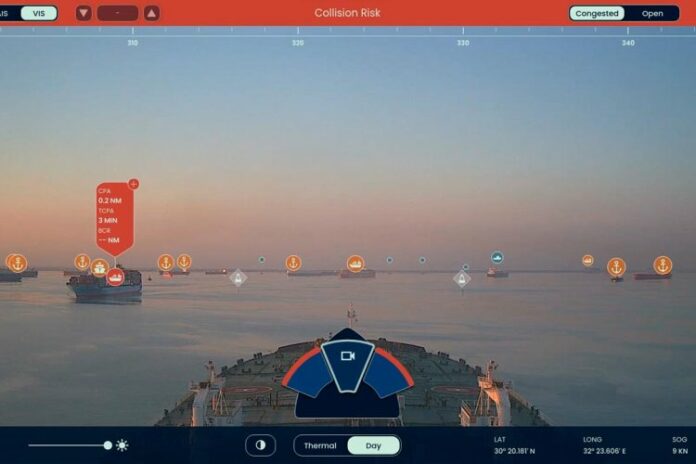

Subsequently, the Houlder team will support the sea trials and demonstration of the wing sail. Sensors will be installed to monitor the performance of the vessel and its engine throughout operations, both before and after the FastRig has been installed, and when the wing sail is both stowed and active. This monitoring will allow calculation and verification of the power savings, and therefore the fuel and emission savings, available from the FastRig, as well as specific items of technical interest such as leeway angle, heel angle and motion damping due to its presence. The data collection and analysis will also support SGS’s computational simulation requirements.

Arun Pillai, Project Director of Houlder, commented:

“At Houlder, we have extensive experience in innovative design and engineering projects with sustainability at their core. We recently interviewed shipowners on maritime clean technology adoption – and a lack of accurate, verifiable and thorough performance data was a key barrier to commercialisation. Together, we are making sure that the performance data of the innovative FastRig wing sail is useful and dependable.”

Diane Gilpin, CEO of Smart Green Shipping, said:

“We are pleased to have received backing from the UK Department for Transport, via CMDC3, for our Winds of Change project. We look forward to continuing to highlight the value and safety of our FastRig wing sail to the shipping industry, particularly as we complete ongoing key project milestones. One such milestone is the calculation and verification of the fuel savings, and resulting emissions reductions, offered by FastRig. We are grateful to have Houlder’s support in this and throughout the project.”

The ‘Winds of Change’ project will act as a testbed and showcase for the FastRig wing sail. Looking ahead, the outcome of this project will be a clean technology with clear, proven safety credentials and processes, as well as verified, thorough data on achievable emissions reductions. The solution can then be deployed across the shipping industry to support the decarbonisation of the global fleet.