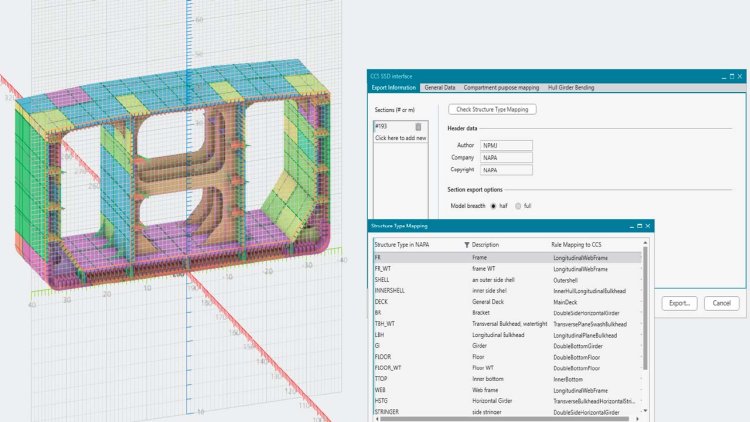

NAPA and China Classification Society (CCS) have introduced a new joint interface between NAPA Steel and CCS’s COMPASS-SDP to streamline the data exchange process between designers, engineers and class societies.

NAPA is the first ship design CAD solution to offer an interface for COMPASS-SDP. The integration will allow 3D structural models created in NAPA Steel to be exported to a data format for 2D hull structure models – ‘SSD-2D’ – which can then be easily imported and processed on COMPASS SDP for further rule calculations.

This integrated process will reduce the modelling time on COMPASS-SDP and improve ship design quality through closer collaboration between teams. More streamlined communication directly on 3D models allows approval engineers to cross-check sections more easily and shorten the approval time. This will enable safer and higher quality ship designs for the industry.

Mikko Kuosa, Chief Executive Officer, NAPA, said:

“The need of the hour across maritime is for greater collaboration for safer and greener ships of the future. Re-shaping the traditional dynamics between engineers, designers and classification societies, and enhancing co-operation, NAPA is proud to be driving change across the industry through the use of 3D models.

“As the industry’s digital capabilities grow, this project with CCS is an important step towards accelerating the adoption of 3D model-based approval and furthering our commitment to a more agile and collaborative process between all parties.”

Zhao Yan, Vice President, CCS, said:

“At CCS, we are committed to supporting a more swift and intelligent design and approval process by making class approval as simple as possible. Today’s announcement to introduce a new interface between NAPA Steel and our COMPASS-SDP will help make this a reality by delivering a more integrated and streamlined process with minimal risk of error and time consumption.”

As part of the project’s first phase, the interface will cover longitudinal structure members as well as geometries and scantling information such as plate thickness, material, and stiffener profiles. This is in addition to other ship data relevant to rule calculation such as frame system, principal particulars, hull girder loads, and compartment data.