Gasum and the Cruise Division of MSC Group have signed a long-term agreement for the supply of LNG to the new flagship of its MSC Cruises brand, MSC Euribia, as well as a Letter of Intent with the goal of cooperating on the supply of synthetic e-LNG made with renewable energy.

The companies also signed a long-term agreement on the delivery of liquefied natural gas, LNG, to MSC’s new flagship MSC Euribia. With this agreement Gasum supports MSC Cruises in cutting emissions with the immediate use of LNG.

Using LNG removes nearly all sulfur oxide and particle emissions, greatly reduces nitrogen oxide emissions and significantly lowers greenhouse gas emissions. In addition, LNG technology on board enables MSC Cruises to switch at any time to fully renewable liquefied biogas (bio-LNG) or synthetic gas (e-LNG) in order to reach greenhouse gas emissions reductions of up to 100 per cent.

MSC Euribia recently demonstrated that emissions neutral cruising is possible already today by sailing the historical first ever net zero greenhouse gas emissions cruise voyage benefiting from the emissions reductions allowed by liquefied biogas procured by Gasum. The ship sailed for four days from Saint-Nazaire in France to Copenhagen, Denmark and utilised bio-LNG with a mass-balance approach, the most environmentally efficient method of delivering the benefits of renewable biogas.

MSC Cruises purchased over 400 tons of bio-LNG from Gasum to show its commitment to the deployment of drop-in renewable fuels and energy transition measures towards the pioneering net zero gas emissions voyage. The line is the industry’s first deep sea ocean cruise operator to buy bio-LNG as a fuel source that proved to allow significant lifecycle emissions reductions.

“Securing a reliable supply of LNG and e-LNG is of critical importance to our decarbonization efforts, and the LOI and long-term agreement that we have announced today are significant steps on that journey. Partnering with Gasum will enable us to access new and cleaner fuels needed to make net zero cruising a reality. We need more suppliers like Gasum to step up and support our industry with its environmental targets. We are ready and waiting to buy more of these new fuels”, Linden Coppell, Vice President of Sustainability and ESG for MSC Cruises, said.

“This LOI on e-LNG is a landmark agreement for the shipping industry as it demonstrates that e-LNG will be available to the maritime transport sector within a short timeframe. We are also very happy about the long-term LNG supply agreement which we believe is the start of long-lasting cooperation”, Mika Wiljanen, CEO of Gasum, stated.

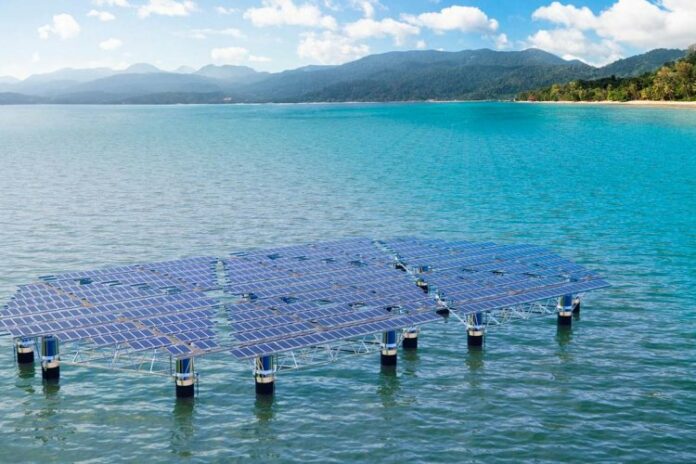

E-LNG gas can be produced synthetically through the Power-to-Gas process. First hydrogen is produced from water using renewable electricity, for example wind or solar power. The produced hydrogen can then be further processed into methane by adding non-fossil carbon dioxide obtained from carbon capture.

This resulting synthetic renewable methane gas is fully interchangeable with natural gas and biogas. When it is liquefied it is likewise fully interchangeable with LNG and liquified biogas. This means that it can be transported through already existing infrastructure – trucks, ships, pipelines also using the existing gas grids.

It also means that synthetic gas can be directly used in the dual fuel engines fitted on board currently running on natural gas, biogas, LNG or liquefied biogas at any ratio. There is no need for any additional investments in new equipment or modifications.

Unlike alternative fuels such as ammonia or methanol which are still in the development stage both in terms of production and infrastructure, synthetic gas, or e-LNG, is a concrete pathway to decarbonizing maritime as well as land transportation in the next few years.