The measurement data will help lower uncertainties in the expected annual energy production for new offshore wind farms. Ørsted, who has patented the USV concept, sees enormous potential in the technology and has initiated a serial production based on their successful prototype USV.

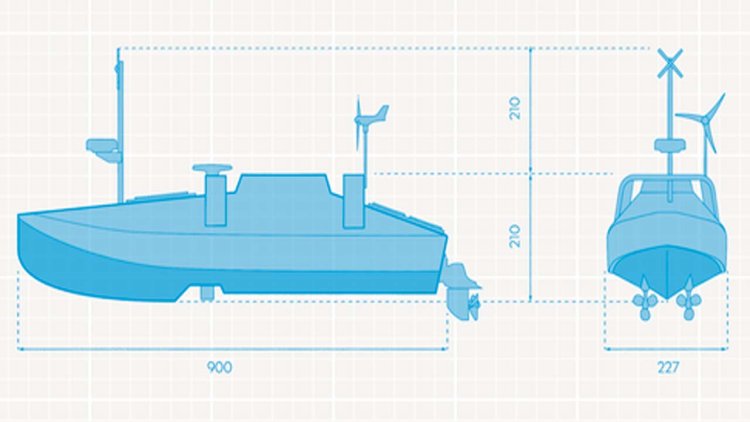

The prototype USV is named Hugin USV. It is designed for continuous operation in the harshest offshore conditions for a year at a time. The USV has a built-in navigation system, which enables it to transit from shore at various degrees of autonomy, and it can be controlled both in line-of-sight or from a beyond-line-of-sight remote control centre.

The USV is designed as a generic sensor platform and can collect large amounts of data on, among other things, the wind conditions, the state of the seabed, and biological and ecological measurements, all dependent on the sensor instrumentation chosen for a given operation. The broad range of measurements collected by the USV is essential for Ørsted’s early-phase development activities prior to the construction of new wind farms.

The USV concept was invented by Ørsted employees and has been patented. The design, development, construction, and testing of the prototype USV was conducted as part of Ørsted’s innovation programme in collaboration with selected industry partners. The prototype USV is constructed by the Danish shipbuilder Tuco Marine Group, and the USV control system is delivered by the innovative Norwegian company Maritime Robotics AS.

Working with small and innovative companies and combining their specialist expertise in vessel construction and autonomous control systems with Ørsted’s in-depth knowledge of offshore measurement operations has been part of the success in delivering a fast time-to-market USV prototype with exceptional performance.

Frederik Søndergaard Hansen, Programme Manager and co-inventor of the USV concept, says:

“What’s so special about our USV concept is that it can bring our measurement equipment to and from our offshore sites without the need for large, specialised support vessels, and, while on site, it can operate autonomously for extended periods of time, measuring large amounts of data that can be sent onshore and processed in real time. The USV concept enables Ørsted to obtain a consistently high data availability, which is essential for achieving the highest possible certainty regarding the annual energy production for new offshore wind farms.

Ørsted’s USV concept has several advantages over conventional solutions that rely on specialised support vessels to bring measurement equipment to offshore sites. The Ørsted USV improves safety by removing the risk for offshore technicians, reduces the overall carbon emissions significantly, and increases the operational window as it can operate safely in high sea state conditions.”

Another benefit of the USV concept is the significantly lowered costs of conducting offshore measurement campaigns, while providing increased flexibility for Ørsted through internal ownership and operation of the USVs. The prototype vessel, Hugin USV, has been tested in Danish and Norwegian waters and has been operational during hurricane conditions, where it experienced waves up to nine metres in the North Sea. Hugin USV has also achieved type validation as a floating LiDAR system by the internationally accredited Norwegian classification society ‘Det Norske Veritas’ (DNV), enabling it to be used for commercial operations related to wind farm development.

“The autonomous vessel is a very good example of Ørsted’s innovation methodology. First, we study the megatrends addressing our industry – in this case, the challenge of obtaining quality wind measurements and environmental data in the fastest time possible. Then, we apply our three-step demonstrator, stepstone, and commercial scale product-to-market recipe. Meaning, we start small and proof the concept, then through strong partnership collaboration, financial backing, and against the tide of macroeconomic trends, we persevere through our extensive inhouse project management experience and systematic problem-solving mindset,” said Jacob Edmonds, Head of Innovation at Ørsted.

The results are so good that Ørsted has started a serial production of a new class of USVs, which incorporates the learnings from the prototype and broadens the operational capabilities to include deep-water operations for future floating wind farms. The USVs in the new class are constructed in Denmark by Tuco Marine Group, and the control systems are delivered by Maritime Robotics, which is a continuation of the good collaboration from the prototype USV. The expectation is to produce five new USVs by the end of 2023.