This equipment scans the entire Antwerp port area and will become the backbone of safe and efficient shipping traffic. Following the recently launched drone network, this represents another important step towards the realisation of a complete digital nervous system covering the area.

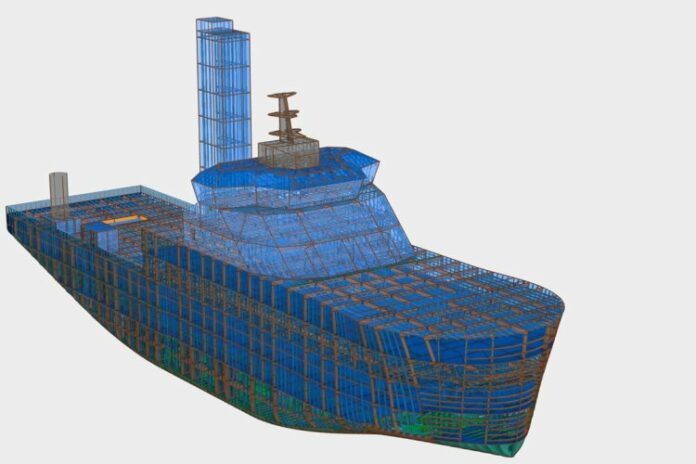

The vast Antwerp port area covers more than 120 km2 with 11,000 hectares of waterways and quays. More than 300,000 shipping movements take place in the port every year. In order to continuously monitor the entire area, as well as all shipping movements, Port of Antwerp-Bruges has expanded and digitised it’s camera and radar infrastructure.

The 460 cameras and 22 radars are directly connected to the Antwerp Coordination Centre and provide operational services such as Vessel Traffic Services (VTS) and the Harbour Master’s Office with a comprehensive view of the port. This allows them to closely monitor shipping and incidents and to manage waterways and moorings more efficiently and safely according to the highest IALA (International Association of Lighthouse Authorities) standards. The images are then viewed and analysed by colleagues with police powers and can also be shared with security services and other authorities.

With this network launching today, the port now has one of the most advanced and high-performance systems of any port in the world. Thanks to the digitisation of the entire network, it is also ready to be connected to APICA (Advanced Port Information and Control Assistant), the port’s digital twin. This digital copy of the entire port area provides a scan every second to create a real-time picture of what is happening at the port based on thousands of pieces of data from a network of cameras, sensors and drones. Operational since 2022, APICA supports port workers to quickly gain visibility into the situation on the ground, and, therefore, to carry out their work more safely and efficiently.

The smart cameras are equipped with specially designed artificial intelligence that allows them to recognise ships. In combination with detailed radar data, this real-time data will further increase situational awareness in the future in order to evolve towards predictive and steering behaviour.

Rob Smeets, Chief Operations Officer Port of Antwerp-Bruges:

“This network is a great asset to our port in terms of safety and operational efficiency. The new sensors form the technological backbone of shipping guidance. In the past, there were a few blind spots in the port area where we had no insight into unexpected shipping movements or incidents.”

Erwin Verstraelen, Chief Digital and Innovation Officer Port of Antwerp-Bruges:

“This network is essential for the further rollout of a digital nervous system across the physical port to support a safer and more secure port. Integrating this data into the digital twin brings us closer to the goal of having a finger on the pulse of what is happening in the vast port area permanently and everywhere.”

Annick De Ridder, Vice-Mayor of the City of Antwerp and President of the board of directors of Port of Antwerp-Bruges:

“This extensive state-of-the-art radar and camera network is a first in the port world. It’s also coming online less than three months after the launch of our unique drone network. This shows that our port continues to invest heavily in the very latest technologies and infrastructure. The aim? To make the Antwerp port area with its 11,000 hectares of waterways and quays one of the safest and most efficiently run in the world and to improve and strengthen our service to customer companies.”