After renting Graviti’s innovative automated dry bulk containers for 2 years and being fully satisfied with the results, the Rigal Central Terminal (in the Freeport of Riga) has decided to purchase six ‘SDC 40’ units from Latvian bulk handling equipment specialist Graviti, even upgrading from ‘SDC30’ types to the bigger ones.

The terminal has an option to acquire six more in the future. The containers have already been delivered and are operational. Having noticed the practical implications and cost-efficiency of the system, several other ports in North-Western Europe, Eastern Europe and the Middle-East have expressed their interest too.

In 2022, more than 150 ships were loaded with GRAVITI containers, handling about 1.5 million tonnes of cargo. There have not been any claims, breakdowns or returns, proving the reliability and effectiveness of this containersized shiploading system, according to Graviti. To date, about 60 SDCs have been sold worldwide.

Dinis Hruscovs, Managing Director of Graviti and responsible for developing the SDC, says:

“We are very proud of this contract with the Freeport of Riga. It shows that we are now truly past the initial stages in which potential clients were interested, but were not yet ready to invest in such an innovation. It has had to prove itself thoroughly in practice and that has turned the table. The fact that our system reduces CO2 emissions in cargo loading logistics also plays a part: the self-discharging containers can handle more bulk faster than traditional grabs, so less movements are needed. Combine that with lower operational cost and a relatively low pricing due to the simplicity of the design and you can see why we are currently speaking with clients in other regions too.”

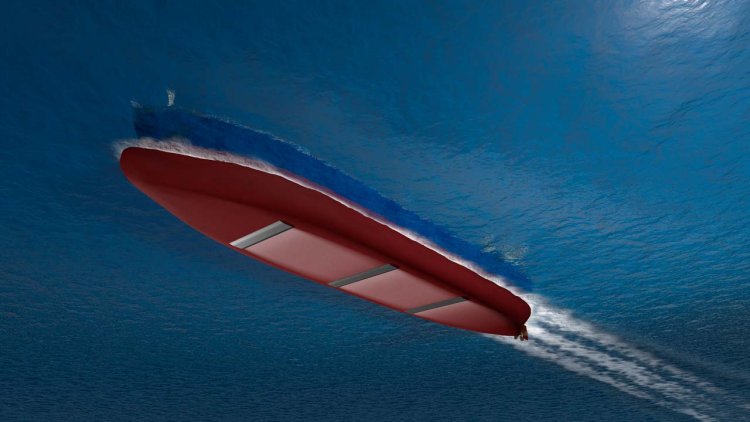

In 2020 Graviti, developed a technology to reduce the costs of loading bulk cargo and speed up the logistics processes at terminals. That resulted in two completely new types of selfdischarging containers, the SDC30, able to handle 600 tonnes of bulk per hour and the SDC 40, with a 900 t/h loading speed, operating with just one crane. After the first types were tested and deployed by, for example, Batumi Port (Georgia) and Riga Universal Port (Latvia), this method became increasingly popular, esp. in eastern European ports.

The containers operate on electrical power and every container comes with its own battery. The floor can be remotely operated to hydraulically open and close. With a fully charged battery, 500 cycles of loading/offloading are guaranteed, although in practice clients report even higher numbers. Because they are self-unloading, they can secure direct loading of dry cargo from warehouses to the ship’s hold.

The SDCs in Riga will be able to unload its 27 m³ cargoes in 30 seconds, which is 1.5 times more productive than regular methods of loading. This method also saves up to 35% of the cost of loading, making it a cost-effective solution.