NOAA and the University of New Hampshire (UNH) are expanding a 24-year ocean and Great Lakes mapping partnership through the creation of a new Center of Excellence for Operational Ocean and Great Lakes Mapping.

“NOAA and UNH have a long history of collaborating to advance the latest technologies and tools to map our ocean, coasts and Great Lakes — a cornerstone of the blue economy,” said Rick Spinrad, Ph.D., NOAA Administrator. “Our continued partnership on the Center of Excellence will help build a workforce ready to tackle the mapping challenges of the future, and further our understanding of our changing ocean and coasts.”

“The University of New Hampshire’s world-class Center for Coastal and Ocean Mapping and Joint Hydrographic Center has led the way for more than two decades in ocean mapping, helping ensure safe marine transportation and understanding coastal hazards. This leadership is affirmed by NOAA locating a new Center of Excellence for Operational Ocean and Great Lakes Mapping on UNH’s campus. With this $8 million NOAA grant I helped secure, New Hampshire’s ongoing research and training programs will remain ahead of the curve in this leading field,” said Senator Jeanne Shaheen, chair of the Senate Appropriations subcommittee that funds NOAA.

The Center of Excellence is funded through $10 million in NOAA’s FY 2023 budget, and will complement existing research, technical expertise and advanced educational programs at the NOAA-UNH Joint Hydrographic Center and UNH’s Center for Coastal Ocean Mappingoffsite link. The Center of Excellence will focus on the following priorities:

- Delivering practical hydrographic training and fostering workforce development for ocean mapping operations.

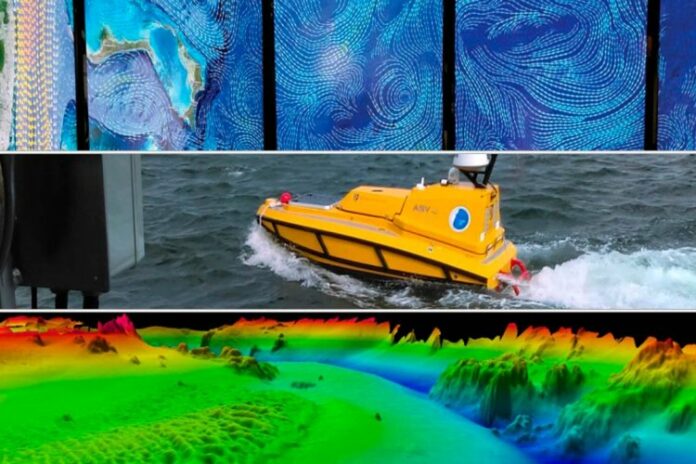

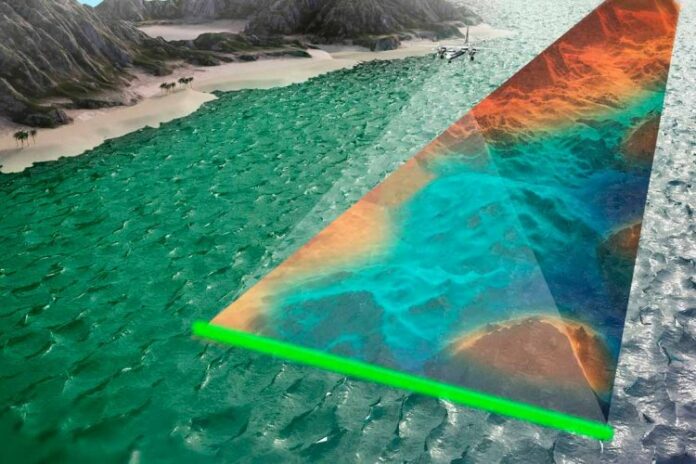

- Providing technical expertise and systems support for NOAA’s mapping operations on an increasingly diverse set of platforms, including new ships and uncrewed survey vessels.

- Partnering with academia and industry to transition ocean mapping research to operations.

“Accurate and up-to-date maps of our ocean, coasts and Great Lakes are critical to maritime commerce, transportation and recreation, and directly support resilient coastal communities,” said Nicole LeBoeuf, director of NOAA’s National Ocean Service. “This new Center of Excellence will build on existing collaboration with UNH as we implement cutting-edge mapping technology and train the next generation of ocean and coastal mapping professionals.”

A portion of the funding will be used by UNH to construct a new, state-of-the-art ocean mapping facility that will serve as the focal point of a campus innovation hub to bring together academia, industry and government.