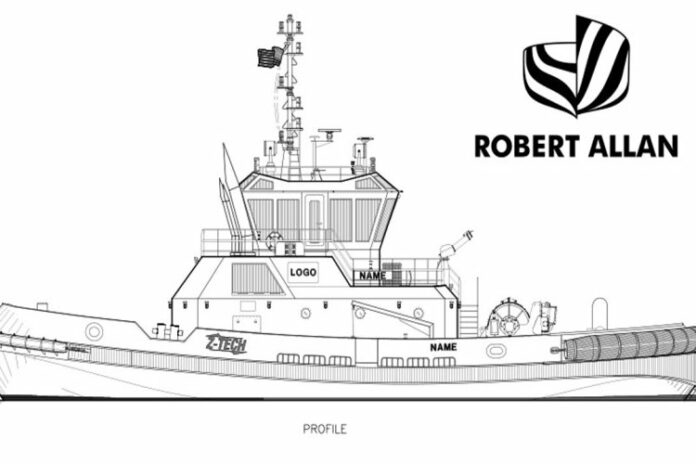

Construction contracts for 4 new tugs have been awarded by Gulf LNG Tugs of Brownsville, Texas to serve the Rio Grande LNG export facility (RGLNG). Master Boat Builders, Coden, Ala. and Sterling Shipyard, Port Neches, Texas will each build two of the Robert Allan Ltd. designed Z-Tech 30-80.

These new tugs are sisters to ten tugs that are currently operating in US Gulf Coast ports. The design has proven to provide exceptional escort performance in combination with superior seakeeping by the blending of two Robert Allan Ltd. innovations: the Z-Tech configuration and the RAstar’s sponsons.

The Z-Tech 30-80 tugs will be classed by ABS for Escort Tug, Low Emissions Vessel (US) and Fire Fighting – Class 1, in compliance with the ABS Marine Vessel Rules, 2023. The tugs are also in compliance with USCG Subchapter-M regulation requirements for towing vessels.

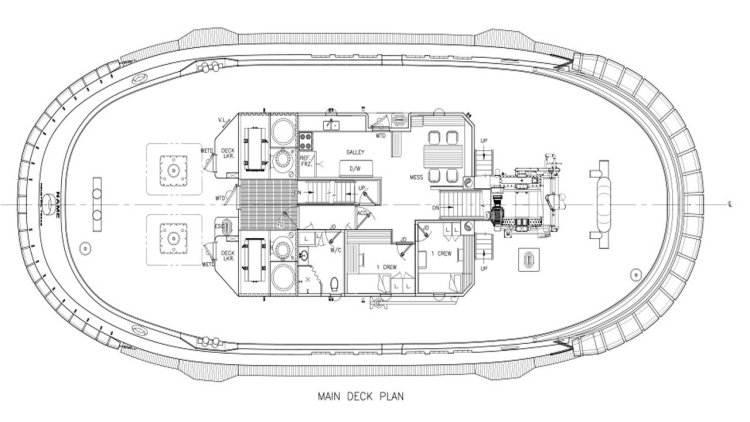

The Z-Tech 30-80 tugs have an overall length of 98’-6”, a breadth of 42’-8” and are expected to reach a bollard pull of approximately 87 tonnes, with a pair of Schottel SRP 510FP thrusters, 2.8 metre fixed pitch propellers, driven by two EPA Tier IV compliant Caterpillar 3516E main engines, delivering 3500 bhp at 1800 rpm. A Markey DEF-48A, Class III – 100HP winch is fitted on the forward deck for escort operations.

Gulf LNG Tugs of Brownsville, Texas is a joint venture formed between Bay-Houston Towing Co., Moran Towing Corporation, and Suderman & Young Towing Company.