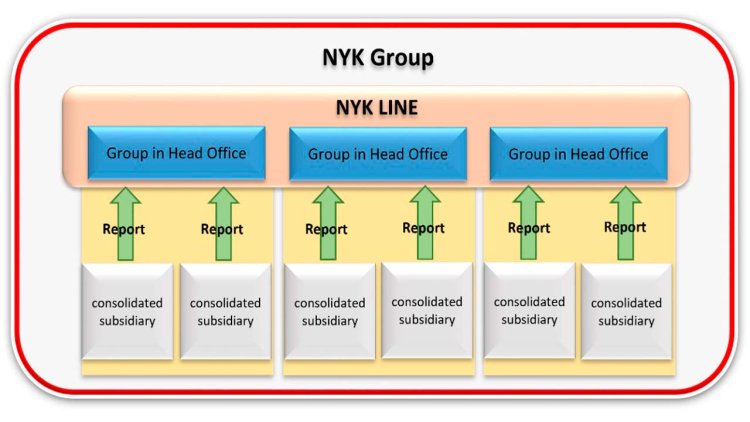

NYK Line and NTT DATA will establish a system to aggregate total greenhouse gas (“GHG”) emissions from the NYK head office and approximately 80 domestic and overseas consolidated subsidiaries by December 2023 to visualize the NYK Group’s GHG emissions in a comprehensive manner.

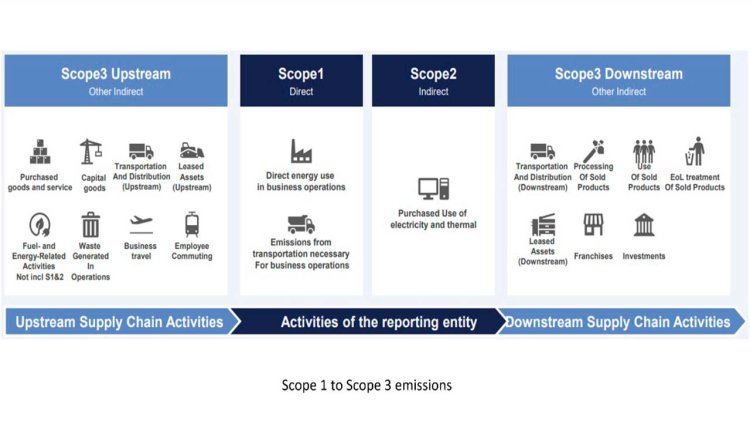

Of the NYK Group’s GHG emissions, all of the following have already been disclosed: Scope 1 emissions, which represent direct emissions from fuel use, etc.; Scope 2 emissions, which represent indirect emissions from electricity use, etc.; and some categories of Scope 3 emissions, which are emissions from other companies related to the activities of the business. However, appropriate aggregation boundaries and calculation methods for all Scope 3 emissions have not been established. This is one of the key challenges for achieving net-zero emissions by 2050.

To resolve this issue, the two companies signed a GHG emissions visualization support consultancy agreement in August and have been working on Scope 3 emissions, for which a compilation system is not yet in place, including the selection of targets for compilation and the examination of a compilation system and calculation logic.

In the future, based on the studies carried out, NYK will establish a system to collect and aggregate Scope 3 emissions data while continuing to utilize the existing aggregation system. By adding Scope 3 data to Scope 1 and 2 data, NYK aims to visualize the GHG emissions of the entire NYK Group, i.e., not only the ship transport business but also all other businesses such as wholesale, manufacturing, and other transport. This will enable quantitative analysis of efforts to reduce GHG emissions and is expected to contribute to more effective GHG emission reductions.

Akira Kono, Representative Director, Executive Vice-President Executive, Officer and Chief Executive of ESG Strategy Headquarters, said:

“NYK Line Given the NYK Group’s wide-ranging business development, one of the challenges has been understanding the full scale of Scope 3 GHG. In addition to the cooperation of NYK Group companies, the establishment of an appropriate calculation system with the generous calculation support provided by NTT DATA is a vital step in our efforts to reduce GHG emissions. We will take the initiative in understanding the GHG emissions of our supply chain and lead the way toward a decarbonized society.”

Isao Arima, Director and Senior Executive Vice President, NTT DATA JAPAN CORPORATION, said:

“In international shipping, countries worldwide have agreed to reduce greenhouse gas emissions to zero by 2050, and more efforts are required to identify and reduce emissions accurately.

NYK has established a system for all its domestic and overseas operations and is working to provide accurate calculations for not only its Scope 1 and 2 emissions but also its advanced Scope 3 emissions. We are very pleased to be able to work together with NYK on this kind of project. NTT DATA will continue to support decarbonization management beyond visualization.”