Neptune Energy and its partners have announced a new discovery at the Kyrre prospect and confirmed the volumes for the Ofelia appraisal well, both located in the PL 929 licence, close to the Gjøa field in the Norwegian sector of the North Sea.

Neptune has completed the Ofelia appraisal well, 35/6-4 ST2, in the Agat formation. The estimated recoverable volume is in the range of 16-33 million barrels of oil equivalent (mmboe).

In addition, the 35/6-4 A side-track was drilled into the overlying Kyrre prospect, resulting in a new gas discovery. Estimated recoverable resources are between 11-19 mmboe of gas, bringing the total recoverable volume from both discoveries to approximately 27-52 mmboe.

Neptune Energy’s Managing Director for Norway and the UK, Odin Estensen, said:

“Confirming the Ofelia volume as well as making another discovery nearby, further strengthens our understanding of the Greater Gjøa Area which is an important growth hub for the business in Norway. The dual discoveries allow for a potential fast track, low cost, and low carbon development.”

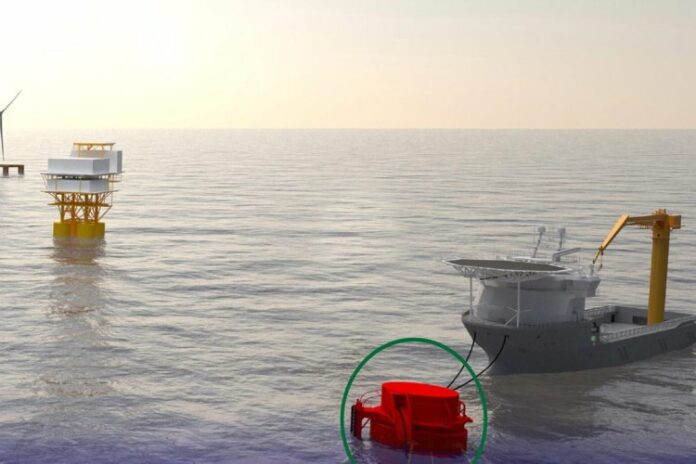

Located 23 kilometres north of the Neptune-operated Gjøa platform, Ofelia Agat and Kyrre will be considered for development as tie-backs to Gjøa. Neptune will also evaluate if the company’s oil and gas discovery Gjøa Nord (Hamlet), with estimated recoverable volumes between 8-24 mmboe, can be jointly developed.

The Gjøa platform is electrified with power from shore and produces at less than half the average carbon intensity of Norwegian Continental Shelf fields1.

Neptune’s Director of Exploration & Development in Norway, Steinar Meland, added:

“The reservoir quality in the Kyrre discovery is very good, which allows for high production rates. We are preparing for several other exciting exploration opportunities in the area, such as the Cerisa well early next year.”

Wells 35/6-4 ST2 & 35/6-4 A were drilled by the Deepsea Yantai, a semi-submersible rig, owned by CIMC and operated by Odfjell Drilling.