The article, “Plastics in the deep sea—A global estimate of the ocean floor reservoir,” was published in Deep Sea Research Part I: Oceanographic Research Papers.

Every minute, a garbage truck’s worth of plastic enters the ocean. With plastic use expected to double by 2040, understanding how and where it travels is crucial to protecting marine ecosystems and wildlife.

Dr. Denise Hardesty, Senior Research Scientist with CSIRO, said this is the first estimate of how much plastic waste ends up on the ocean floor, where it accumulates before being broken down into smaller pieces and mixed into ocean sediment.

“We know that millions of tons of plastic waste enter our oceans every year but what we didn’t know is how much of this pollution ends up on our ocean floor,” Dr. Hardesty said.

“We discovered that the ocean floor has become a resting place, or reservoir, for most plastic pollution, with between 3 to 11 million tons of plastic estimated to be sinking to the ocean floor.

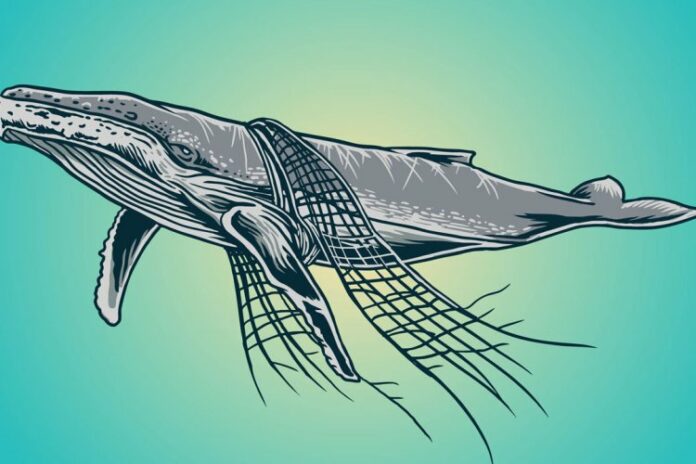

“While there has been a previous estimate of microplastics on the seafloor, this research looks at larger items, from nets and cups to plastic bags and everything in between.”

Alice Zhu, a Ph.D. Candidate from the University of Toronto who led the study, said the estimate of plastic pollution on the ocean floor could be up to 100 times more than the amount of plastic floating on the ocean’s surface based on recent estimates.

“The ocean surface is a temporary resting place of plastic so it is expected that if we can stop plastic entering our oceans, the amount would be reduced,” Zhu said.

“However, our research found that plastic will continue to end up in the deep ocean, which becomes a permanent resting place or sink for marine plastic pollution.”

Scientific data was used to build two predictive models to estimate the amount and distribution of plastic on the ocean floor—one based on data from remote operated vehicles (ROVs) and the other from bottom trawls.

Using ROV data, 3 to 11 million metric tons of plastic pollution is estimated to reside on the ocean floor.

The ROV results also reveal that plastic mass clusters around continents—approximately half (46%) of the predicted plastic mass on the global ocean floor resides above 200 m depth. The ocean depths, from 200 m to as deep as 11,000 m contains the remainder of predicted plastic mass (54%).

Although inland and coastal seas cover much less surface area than oceans (11% vs. 56% out of the entire Earth’s area), these areas are predicted to hold as much plastic mass as does the rest of the ocean floor.

“These findings help to fill a longstanding knowledge gap on the behavior of plastic in the marine environment,” Zhu said.

“Understanding the driving forces behind the transport and accumulation of plastic in the deep ocean will help to inform source reduction and environmental remediation efforts, thereby reducing the risks that plastic pollution may pose to marine life.”

This research is part of CSIRO’s Ending Plastic Waste Mission, which aims to change the way we make, use, recycle and dispose of plastic.