Provaris Energy Ltd and Norwegian Hydrogen AS has announced a new Collaboration Agreement to jointly progress the identification and development of several sites in the Nordic region for the large-scale production and export of hydrogen to European markets.

The projects will utilize locally available renewable energy to produce hydrogen for shipment to European ports. This will assist energy-intensive industries in making an impact on their decarbonization plans and target a scale and level of innovation that aligns with various European Union funding schemes.

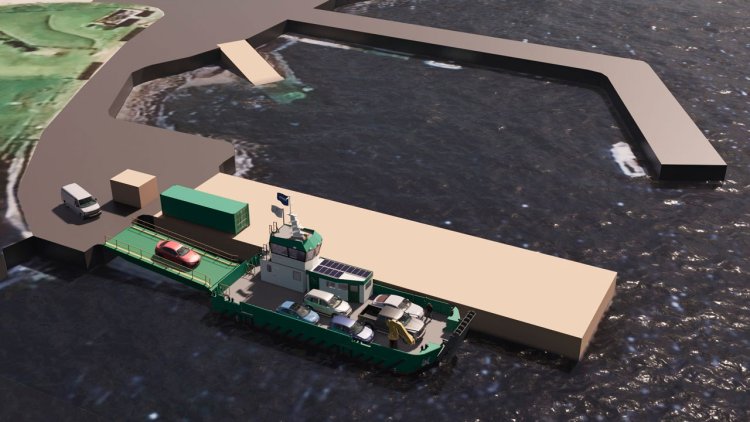

New projects will be strategically located in areas with robust grid connections and power supplies. These sites will facilitate the construction of state-of-the-art electrolyzers, and hydrogen compression facilities linked to export jetties. Provaris’ H2Neo carriers will transport the hydrogen, while the H2Leo barge will serve for storage. The initiatives will also foster circular economies by utilizing by-products like clean oxygen and waste heat in local industries and district heating systems.

Jens Berge, Norwegian Hydrogen’s CEO commented:

“While we develop a comprehensive network of production sites and distribution infrastructure across the entire Nordic region, to reduce emissions in the Nordics, we have also identified several sites with significant export potential. While such locations could also be used to produce other derivatives such as e-methanol or green ammonia, we strongly believe that if the end demand is for gaseous hydrogen, nothing would be better than to avoid going via a derivative solely for transportation purposes. Provaris’ technology makes it possible to bring hydrogen in gaseous form all the way from production in the Nordics to the customers in continental Europe.”

Martin Carolan, Provaris Managing Director and CEO added:

“A new collaboration with Norwegian Hydrogen for greenfield sites in the Nordics builds on the success of our work together in 2023 and the platform they have developed in the Nordics as a producer of hydrogen. This partnership can accelerate development sites that will leverage Provaris’ downstream activities for supply of green hydrogen to German utilities who are seeking regional volumes of green hydrogen, and more recently, the joint development of a compressed hydrogen import terminal with Global Energy Storage (GES) at the Port of Rotterdam can provide market access to industrial offtake markets within the port and broader Europe.”