Tototheo Global and Neuron have announced an agreement to deploy Neuron’s AI-powered quality of experience (QoE) management platform to vessels contracted to Tototheo.

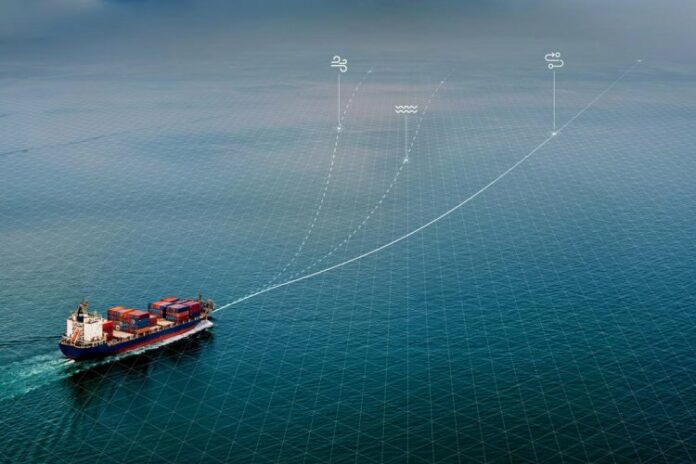

Through this partnership, Tototheo Global and Neuron will address a growing need for ships as they increasingly engage with multiple satellite providers and networks – the need for increased transparency and technologies to help vessels switch seamlessly between different service deliveries.

The agreement follows proof of concept tests verifying that Neuron’s QoE analytics solution, Neuron 360, enhances connectivity robustness with deep insights that can be used to improve onboard connectivity operations and performance. With this partnership Tototheo Global and Neuron will work with customers to integrate real-time connectivity data from the antennas, routers and third-party systems on their ship’s end-to-end network, providing a holistic view of their connectivity and QoE on one vendor-neutral platform.

“Multi-network services are becoming widespread in commercial shipping, which makes it critical that there is transparency for the end user on the performance management of connectivity as a whole,” said Despina Panayiotou Theodosiou, co-CEO Tototheo Global. “Neuron 360 will ensure more uptime by bringing the visibility that makes it easier, quicker and less costly to resolve shipboard communication issues.” Neuron 360 will be offered as an additional reporting tool for Tototheo Global customers.

Ms. Panayiotou Theodosiou added that Tototheo is part-way through a proof of concept with Neuron Grid, an AI-powered network management solution that enables intelligent network orchestration across multiple providers, orbits and networks. Neuron Grid integrates connectivity services offered via LEO, MEO, GEO, 4G, 5G and/or Wi-Fi and consolidates them into a single channel. It then intelligently routes traffic across all available services and providers to ensure reliable coverage in any location at the most optimal QoE, while also managing bandwidth and cost constraints.

“We see Neuron Grid as an added value solution which will help clients reduce their costs in network management, freeing up resources, while ensuring a high-quality experience and delivering even more robust network connectivity,” said Ms. Panayiotou Theodosiou. “In partnership with Neuron, Tototheo will deliver a market leading AI-driven solution for network management.”

“In the era of multi-network satellite service provision for ships, the speed, accuracy and constant availability of AI to optimise routing selection will drive better connectivity performance while also eliminating the operating time and money lost to manual interventions,” she said.

“Intelligent multi-provider, multi-orbit orchestration will unlock a number of new use cases for shipping companies, with the ability to quickly scale from a few megabits to hundreds as needed, while keeping QoE high and total cost of ownership low,” said Benny Retnamony, founder and CEO of Neuron. “Through our partnership with Tototheo, we look forward to bringing the Neuron platform to more companies to help accelerate the future of smart shipping.”