Svitzer has announced the signing of a contract with Shipyard Rio Maguari for the construction of three new tugboats.

Brazil plays an essential role in the global economy, particularly in the trade of grains, oil and metals. The nation’s vast agricultural output makes it a critical supplier of grains, ensuring food security for countries reliant on imports. Additionally, Brazil’s significant oil production and refining capacity contribute to global energy security. Its abundant metal reserves are essential for industrial development and manufacturing worldwide.

These exports collectively foster economic growth and development within Brazil, further solidifying its position as a key player in international trade. As enablers of trade, Svitzer is committed to supporting this growth by investing in additional tugboats for its Brazilian fleet

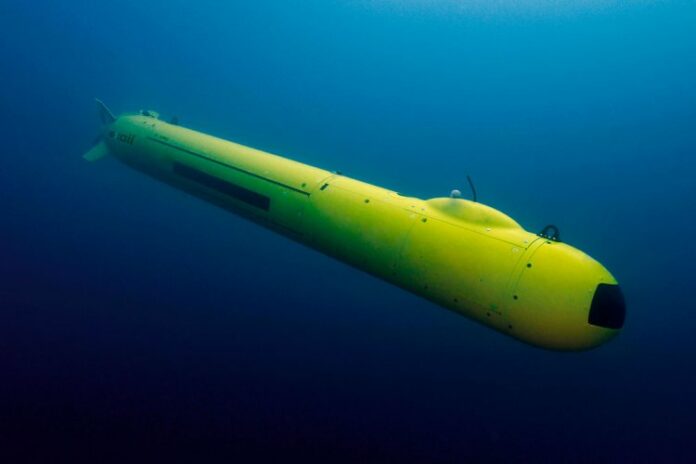

The three vessels currently under construction are part of the 2300 Rampart Series and boast a top speed of 13 knots, an overall length of 23.2 meters and a bollard pull of >70 tonnes. The vessels will be equipped with Fifi-1 firefighting capabilities. These advanced features will enhance Svitzer’s ability to support the growing capacity of various Brazilian ports, ensuring safe, reliable and efficient customer services.

Arjen van Dijk, Managing Director for Svitzer Americas, emphasised the strategic importance of this investment:

“Svitzer’s new build program in Brazil is a testament to our continuous commitment to meet the evolving needs of our customers in this important market. These tugboats are designed to handle the increasing complexity and volume of Brazil’s maritime operations and will enhance our operational capacity across various Brazilian ports. It not only strengthens our service offerings but also aligns with our broader goal of supporting Brazil’s economic growth and infrastructure development.”

Daniel Reedtz Cohen, Managing Director of Svitzer Brazil, highlighted the continuous growth opportunities in the region:

“Brazil’s economy has seen significant growth in the green energy and agricultural export sectors and has a key position in the global energy and food supply. Furthermore, the country’s growing export market for commodities, such as metals and oil, demonstrates its economic potential. With the number of ports increasing, and new terminals under construction, the expansion of our fleet with these tugboats reflects our dedication to supporting the evolving needs of Brazilian ports. We see continuous growth opportunities in the country, and this investment positions us to continue meeting new demands effectively.”