RINA Type Approval confirms that the Blue Whale ESS complies with RINA Rules for the Certification of Lithium Battery Systems. This approval, along with recently awarded type approval from DNV, demonstrate that the large-scale energy storage system complies with the most stringent rules, regulations, and safety requirements in the industry, as defined by leading maritime class societies.

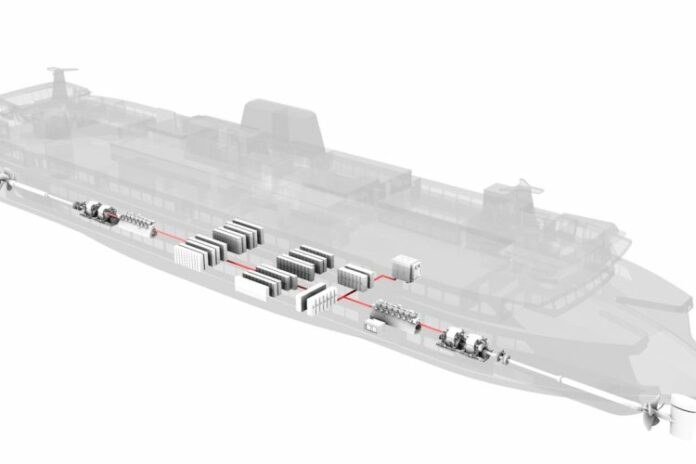

The result of a multimillion-dollar development program, the Blue Whale ESS is designed specifically for large vessels, like Cruise Ships, Ro-Pax and Service Operation Vessels (SOV), and vessels that require a large amount of energy.

The Blue Whale design incorporates the unsurpassed safety features of the Corvus Orca ESS, the world`s most installed marine energy storage system, along with additional features that make it better equipped to meet the energy demands of large vessels.

For example, optimized energy density enables the Blue Whale to deliver more power. This in turn can extend the vessel’s ability to achieve and maintain zero-emission operations, including during transit through emissions-restricted zones and port stays.

“We’re pleased that the Blue Whale ESS design has now received type approvals from both RINA and DNV, meeting the highest safety standards in the industry,” says Fredrik Witte, CEO of Corvus Energy.

He adds, “a large-scale battery system designed to meet the energy demands of larger vessels, including cruise ships and large passenger and vehicle transport vessels, is key to support the advancement of maritime decarbonization and emissions reduction efforts.”

In addition to securing type approval from RINA and DNV, Corvus Energy is pursuing type approval from BV and ABS for the Blue Whale ESS.

Both the RINA and DNV Type Approvals for the Blue Whale ESS include approval of the North American-based production facility where the Corvus Blue Whale product is produced, which is located in Canada outside of Vancouver.

More than fifteen Blue Whale orders, cumulatively totaling over 95 MWh, are already confirmed for delivery in 2024, 2025 and 2026, and the production facility is scaled for future capacity needs.