Damen Shipyards Group has announced the selection of its Landing Ship Transport (LST) 100 design by Naval Sea Systems Command (NAVSEA). According to the navy, up to 35 LST100 vessels will be constructed at shipyards in the United States for the Medium Landing Ship programme (LSM).

NAVSEA released the RFI (Request for Information) to the industry at the beginning of 2025. Following this, in July, Damen received a Technical Data Package (TDP) award from NAVSEA for the LST100. The design has now been selected as the basis for the LSM class, following which up to 35 LST100s will be constructed at American yards. To ensure speed of delivery to the fleet, the Navy was seeking a non-developmental sea-going vessel design. Damen has previously delivered an LST100, providing the opportunity for NAVSEA representatives to visit an in-service example for themselves.

Additionally, last year, the Australian Government announced its selection of the LST100 for the Australian Defence Force’s Landing Craft Heavy programme. With this, up to eight of the vessels will be constructed by Australian shipyards.

Damen has supported shipyards around the world with the construction of its designs since 1977. We provide everything from a licensed design to a materials package, to building support.

In this way, over 150 Damen-designed vessels have been built in the USA to date. This includes the Sentinel Class and Protector Class patrol vessels in operation with the US Coast Guard.

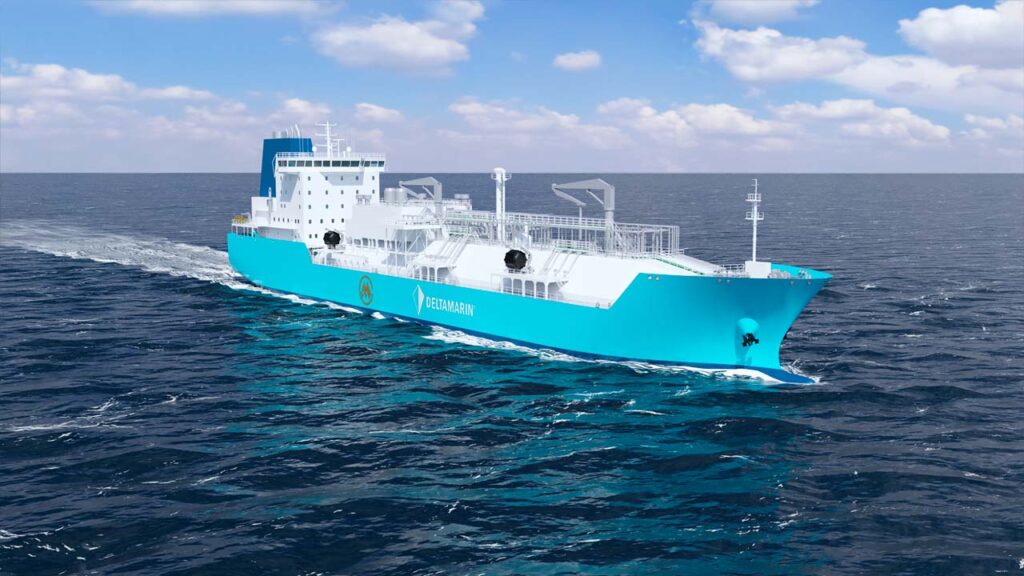

The LST100 is 100.68 metres long with a beam of 16 metres and a draught of 3.58 metres. It is suited to a diverse range of operations. With its ability to transport personnel, vehicles, equipment and cargo, the vessel can be used in patrol, landing, survey and reconnaissance operations, as well as for the delivery of humanitarian aid & disaster relief.

In its standard design it features bunks for 282 personnel. Cargo can be transported on the RoRo deck (500m2), vehicle deck (400m2) and on the helicopter deck. The vessel is able to sail at speeds of up to 14 knots, with an endurance of 3,890 nautical miles. At endurance speed of 10 knots, it can reach up to 7,530 nautical miles.

The LST100 features extensive flexibility. Its modular design enables straightforward adaptation and upgrade without compromising the benefits of standardisation. For example, with the addition of a standard, 20-metre modular block, the vessel can be enlarged to the LST120 design during construction.

Damen Area Manager Americas Alan Borde said, “We are delighted at NAVSEA’s selection of the LST100 for its LSM programme. We are very much looking forward to continuing our cooperation with American shipyards during the construction of these vessels in the coming years. We enjoy long-standing relationships with a number of these yards, having supported their construction of our vessel designs over the last decades.

“I would like to thank the Embassy of the Netherlands in the USA, as well as my colleagues at Damen Naval, for their support in the process so far. And of course, my extreme gratitude goes to NAVSEA for placing their trust in Damen. The LST100 has proven itself in operation already, and we have full confidence in the design’s suitability to meet the operational requirements of the US Navy.”