Damen Shipyards Group has delivered the second in a series of two Offshore Patrol Vessels (OPV) 2600 to the Pakistan Navy.

The vessel, named PNS Yamama, follows the delivery of the PNS Hunain in summer 2024. This latest delivery marks a milestone moment in a long-term relationship beginning with Damen’s earlier construction of the two Yarmook Class vessels, based on the Damen OPV 1900, in 2020. The handover ceremony for the PNS Yamama took place on 17th December at Constanta in Romania.

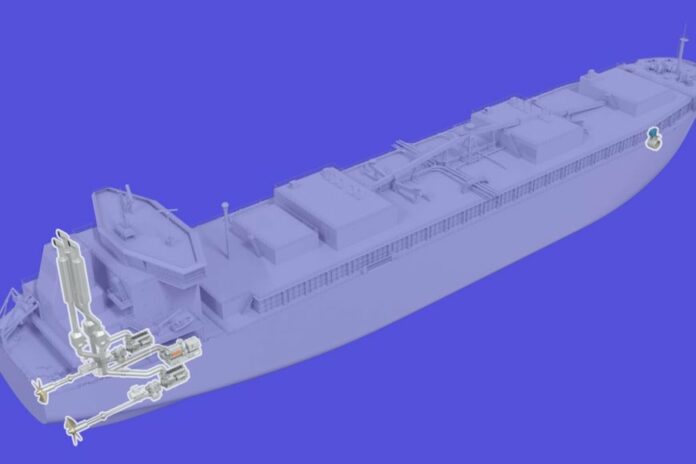

The second batch OPVs feature a displacement of 2600 tons and are 98 metres in length. They are suited to a wide range of maritime operations including maritime security and military operations other than war.

Speaking during the ceremony, Vice Admiral Muhammad Faisal Abbasi, said,

“The Offshore Patrol Vessels project is an ultimate success not only for Pakistan but for Damen, the Galati Shipyard and all co-makers involved in the conception, design, construction and commissioning of the four OPVs. I am confident that the collaboration between the Pakistan Navy and Damen will further extend to new avenues for shared gains.”

The OPV project has brought both the Pakistan Navy and Damen to new levels of enhanced cooperation in diverse fields. The delivery of the fourth OPV comes at a time of increasing collaboration as the two parties signed a memorandum of understanding (MoU) during the International Defence Exhibition and Seminar (IDEAS) in Karachi in November.

The MoU demonstrates Damen’s commitment to supporting the Pakistan Maritime Science and Technology Park (PMSTP), an initiative recently unveiled by the Pakistan Navy. With the creation of a central hub close to the University of Bahria, Karachi, the PMSTP looks to foster collaboration between the authorities, industry and researchers, towards innovation and advancement in maritime technology.

As part of its scope as a PMSTP partner, Damen will be supporting the establishment of a local service centre to provide maintenance and services to Damen vessels operating in the region, such as the Pakistan Navy’s OPVs. Damen will collaborate with local businesses on shipbuilding projects, leveraging the advanced design and engineering capabilities it will develop as a partner in the PMSTP, enabling the joint design and development of new vessels for the Pakistan Navy.

Damen Regional Sales Director Stephan Stout said,

“The PMSTP initiative aligns well with Damen’s way of working. Wherever we are operating in the world, we look to cooperate with local governments, industry, and education and research institutes. We believe that, in this way, our shipbuilding projects can provide a boost to domestic industry and local employment, while at the same facilitating the development of a strong local supply chain. We’re looking forward to collaborating with our partners in Pakistan and playing our part in advancing a sustainable maritime industry in the country for the long-term.”