The technology group Wärtsilä has launched a new series of power limitation solutions that enable compliance with the IMO’s Energy Efficiency Existing Ship Index (EEXI) regulation.

The EEXI regulation comes into effect in 2023 and stipulates the minimum energy efficiency level for existing ships already in service. Wärtsilä’s new power limitation systems allow owners to meet this requirement, despite the tight implementation schedule. Wärtsilä’s environmental offering also includes various energy efficiency solutions that enable compliance with the IMO’s Carbon Intensity Indicator (CII) requirements, which form part of the IMO’s strategy for reducing greenhouse gas emissions from shipping.

For meeting the EEXI requirements, three macro areas are relevant, namely Power Limitation, Energy Efficiency technologies, and Fuel upgrades. With the introduction of these latest power limitation solutions, Wärtsilä covers all three areas with proven solutions, and can thus recommend the optimal choice for meeting the specific needs of owners and operators.

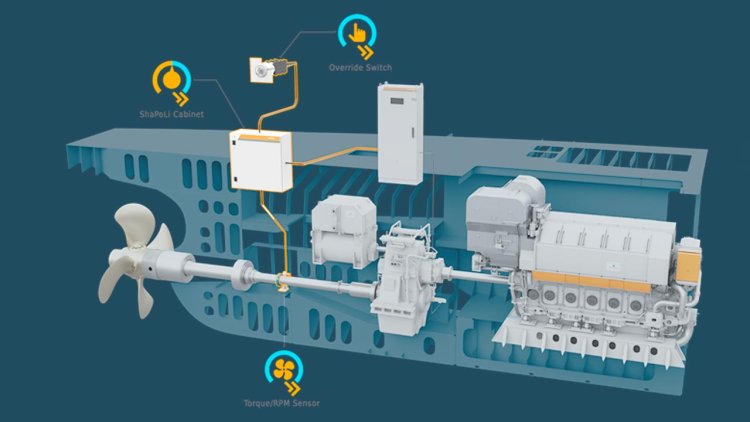

The power limitation upgrades being launched by Wärtsilä are verified and approved systems. They comprise Engine Power Limitation for 4-stroke engines, Engine Power Limitation for 2-stroke engines, Shaft Power Limitation for vessels with a controllable pitch propeller (CPP) and a Wärtsilä Propulsion Control System, and Power Limitation specifically dedicated to diesel-electric installations.

The upgrades effectively limit the engine or shaft power during normal operation, regardless of the power train combination and control system arrangements. The set limits of the solutions can all be overridden from the bridge. This is a mandatory feature stipulated by the IMO / MEPC guidelines, as are the monitoring and recording functions. The system data is stored in accordance with the regulations for inspection purposes.