Robert Allan Ltd. is pleased to announce that TOR Group of Companies’ (TOR) shipyard in Tuzla Bay (Istanbul), Turkey has successfully delivered the Ben Owusu-Mensah, the third of three RAstar 3300 tugs for Ghana Ports & Harbours Authority (GPHA). With keels for all three tugs laid on February 19th of 2019, these deliveries are especially notable for the speed of construction.

These three new tugs are equipped to fulfill a multitude of missions for the GPHA, including but not limited to ship-assist, fire-fighting, and pollution response. Driven by high speed engines and Z-drive propellers, the Ben Owusu-Mensah and its sisters comfortably meet all contractual performance requirements, including the achievement of 82 tonnes of bollard pull and speeds in excess of 14 knots on trials.

Each of these tugs is well equipped for GPHA’s ship-handling and towing needs, with a Kongsberg hawser winch forward, with 225 tonne brake holding load, and a 100-tonne safe working load Mampaey tow hook mounted to a tow post aft.

Main propulsion machinery is comprised of the first Cummins QSK95-M engines used in a tug application, each delivering 2,560 kW at 1800 rpm, and driving 2.8 metre diameter Kongsberg US255S P30 fixed pitch Z-drives. Electrical power is generated by a pair of Cummins QSB7 gensets, each capable of producing 136 ekW at 50 Hz.

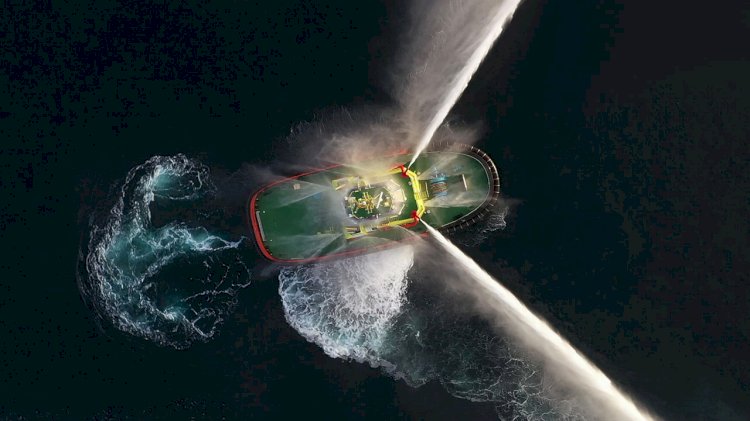

The Fi-Fi 1 class off-ship fire-fighting system is powered by a dedicated Cummins QSK38-M1 engine, driving a single 2,750 m3/hr Marsis fire pump. A pair of Marsis water and foam capable monitors are mounted on the forward deckhouse top and include fog/jet nozzles. A water spray system is also outfitted.

In addition to their primary ship-handling and fire-fighting duties, the tugs feature tankage for recovered oil, with a corresponding oil recovery notation. A Heila 25-2S folding knuckle boom crane on the aft deck of each tug provides additional utility with 8.6 metre reach.

Spacious and climate-controlled MLC 2006 compliant accommodations provide comfort for a crew of up to 8 persons, even on days where exterior temperatures may rise as high as 50o C. Two single officer cabins with ensuite WCs are located in the deckhouse, along with large and well appointed galley and mess spaces. Three large double cabins, all well in excess of MLC area requirements are located below deck, along with a common lavatory space. A generous galley store is also located on this deck, as is the air-conditioned switchboard room.