Delivered safely, on time, and within budget, Wind Pace becomes the seventh vessel in Cadeler’s growing portfolio of wind turbine installation vessels, further strengthening the company’s capacity to meet the increasing global demand for large-scale renewable energy solutions.

Wind Pace was officially named at a naming ceremony on the 12 March at the COSCO Shipping Heavy Industry (COSCO) shipyard in Qidong, China, where she was built.

After her delivery, Wind Pace will be deployed in the U.S. under a contract from Q2 2025 to Q1 2026, supporting a project at an offshore wind farm in the region, Cadeler’s second project in American waters.

Her sister vessel, Wind Peak, the first of Cadeler’s two newbuild P-class vessels, was delivered in August 2024, and has just embarked on her first installation project, the Sofia Offshore Wind Farm, off the Yorkshire coast of the United Kingdom – one of the largest single offshore wind farms in the world.

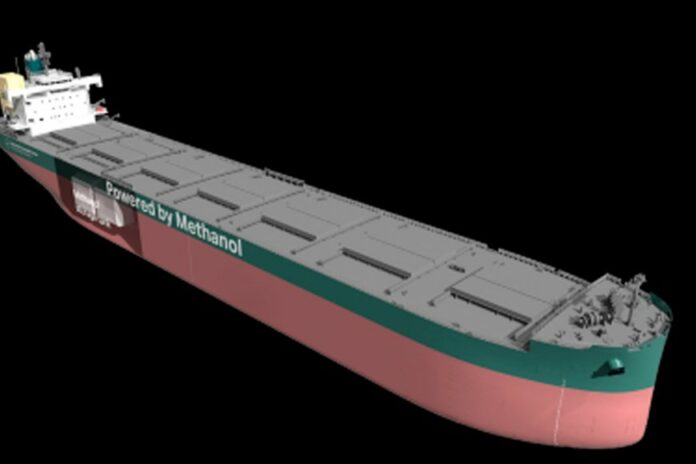

Wind Pace is specifically designed to handle the increasing size, scope, and complexity of next-generation wind farm projects as well as the most challenging offshore conditions.

The P-class vessels are capable of transporting and installing up to seven complete 15 MW turbine sets per load or five 20+ MW turbines, reducing the number of roundtrips required and significantly accelerating installation time while improving energy and cost efficiency. An advanced hybrid power system and cyber-secure operational infrastructure ensure high efficiency and enhanced safety.

“The P-class vessels set a new benchmark in offshore wind installation technology. With advanced crane capabilities, enhanced transit effectiveness, and reduced energy intensity, these vessels unlock new levels of efficiency for our customers. Wind Peak, the first P-class vessel, has already fully demonstrated this since her delivery last year. Likewise, we expect Wind Pace to play a key role in supporting our clients in the necessary expansion of offshore wind,” says Mikkel Gleerup, CEO of Cadeler.

Being the largest vessels in the Cadeler fleet today, both Wind Peak and Wind Pace boast a deck space of 5,600 m², a payload capacity of over 17,600 tonnes, and a main crane capable of lifting 2,600 tonnes at 47 meters. Additionally, each vessel can accommodate up to 130 crew members and installation technicians.

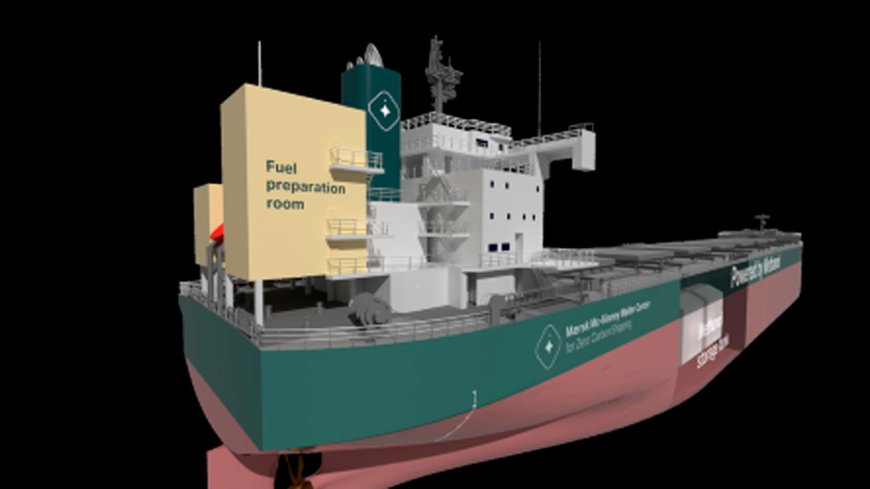

“Cadeler has always looked for new ways to provide better solutions for our customers whilst remaining conscious of the increasing need for sustainability in our industry. The P-class vessels exemplify this commitment with a design prepared for future dual-fuel green-methanol operations and an electrical system that captures and stores excess energy for re-use,” Gleerup noted.

The P-class vessels are the result of close cooperation between Cadeler and its key partners on these newbuildings, including COSCO, GustoMSC, NOV, Kongsberg, Huisman, and MAN Energy.