Provaris Energy Ltd has executed a Memorandum of Understanding (MOU) with Norwegian Hydrogen AS to collaborate on the development on green hydrogen value chain projects in the Nordics.

The MOU provides a framework to jointly undertake a Concept Design Study to:

- Review identified sites and select a preferred location suitable for domestic and export volumes of hydrogen.

- Undertake a technical and economic review for the production and supply of compressed gaseous green hydrogen to nominated European ports.

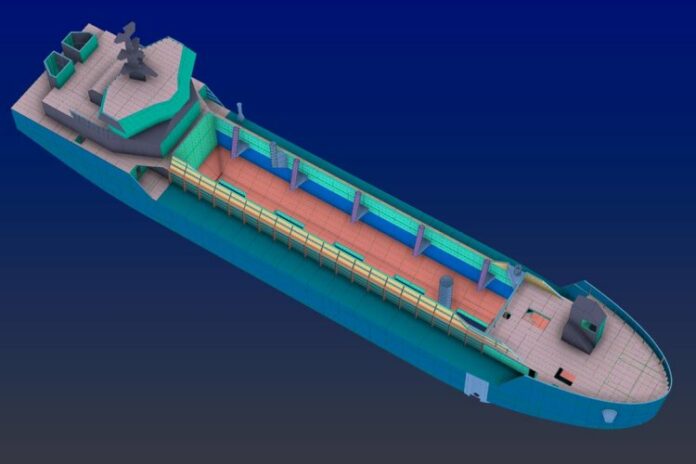

The scope of the study will include the renewable power supply, production of hydrogen, compression facilities, storage, infrastructure for jetty loading and unloading, Provaris’ H2Neo carrier, and import infrastructure required at identified import locations. Application for suitable funding schemes available through national schemes and the European Union will also be made.

Martin Carolan, Provaris Managing Director and CEO commented:

“The Nordic region offers several advantages that can include low-cost hydro power, proximity to offtake markets and supportive governments committed to supplying hydrogen to Europe. This collaboration also has strategic alignment with the development timeline of our H2Neo carrier and validation of the increasing interest for our compressed H2 transport solution for hydrogen supply into Europe.”

With the goal of an export supply chain to be in operation by 2027, the first step will be the completion of a Design Concept Study by the end of 1H2023, at which time the parties will agree on the location and scale of the first fast-track production and export project, responsibilities and timing for a detailed feasibility, along with the identification of additional collaboration partners to establish a green hydrogen value chain and export facility in the Nordics.

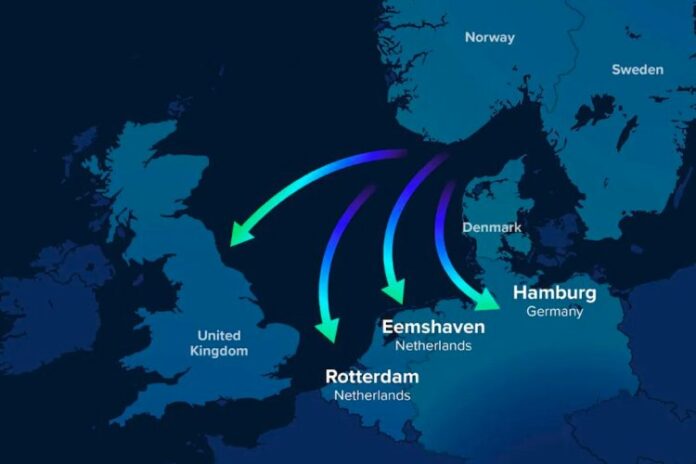

Provaris and Norwegian Hydrogen will focus on identified sites for green hydrogen export, with a short sailing distance to some of the major planned hydrogen import hubs in Netherlands and Germany. This includes sites in Norway, where the government recently announced its agreement with German counterparts for the export of hydrogen. Potential import hubs in the United Kingdom could have equivalent, and advantageous proximity to source location(s). At these short distances, Provaris’ proprietary compressed hydrogen H2Neo carrier has demonstrated to be very cost competitive compared to alternative transportation, storage and conversion vectors of hydrogen. The scope of the MOU will focus on the development of the full value chain, including production, maritime transportation, and distribution to off-takers.

Germany and the Netherlands are considered key import locations in the European Union, and both countries are well advanced in planning and developing hydrogen backbones / pipelines that allows for advantageous integration and operations with Provaris’ compressed hydrogen solution.