Offshore hydrogen production is paramount to meet the substantial increase expected in European hydrogen demand. Hydrogen is due to play a significant role as a low-carbon energy carrier, not only to decarbonize hard-to-abate sectors, but also to boost security of energy supply in Europe.

The “Specification of a European Offshore Hydrogen Backbone” study, commissioned to DNV by infrastructure system operators GASCADE and Fluxys, highlights the significant advantages of an offshore hydrogen backbone in the North and Baltic Seas.

The potential energy generation from offshore wind in the North Sea and Baltic Sea is immense, and possible greater than what the electricity system alone can handle. The DNV study finds that offshore hydrogen production connected by pipeline is cheaper than onshore hydrogen production. The pipeline connection and high load factors make the North and Baltic Sea some of the lowest cost sources of green hydrogen for North-western Europe.

“The EU expects demand for climate-neutral hydrogen to reach 2,000 terawatt hours (TWh) by 2050, and DNV sees the potential to produce 300 TWh/a of hydrogen using electricity from offshore wind farms in the North Sea by 2050. This would make a significant contribution to reducing dependence on energy imports. This positive aspect for increasing supply security can hardly be valued highly enough after the experiences of the recent past”, says GASCADE Managing Director Ulrich Benterbusch.

Given the lower costs of hydrogen transmission compared to electricity and the possibility for large pipelines to aggregate offshore hydrogen production from several windfarms, the report assesses that offshore hydrogen production is an attractive option for offshore wind production, certainly at distances of more than 100 km from shore.

With regards to transport infrastructure, the study draws two different pictures based on location:

For the North Sea, a large area and production potential meet the 100 km criterion. To bring the hydrogen produced offshore to land, a meshed pipeline connection – a European backbone – could sensibly connect production sites to the existing onshore pipeline network.

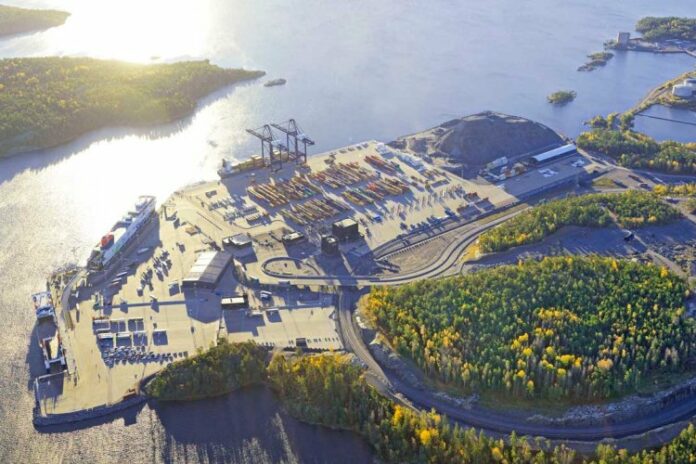

The situation is somewhat different in the Baltic Sea region, where fewer areas currently meet the 100-km criterion. However, if Sweden and Finland decide to produce hydrogen on a large scale and transport it to demand centers in Central Europe, a combined pipeline is likely to make sense there as well.

The spatial distribution of the potential offshore hydrogen production sites shows that the sea areas of different countries are involved.

“This suggests that transnational coordination will be necessary to develop the full identified hydrogen generation potential”, says Christoph von dem Bussche, Managing Director of GASCADE.

It will be equally important to strike the right balance between the potential use of wind for electricity generation and the potential generation of hydrogen across countries. To further optimize this hydrogen supply chain, the study suggests storing up to 30% of the produced hydrogen in salt caverns to efficiently increase the flexibility of the system. To support the political discussion, the study also contains an initial cost estimate: in the North Sea, the cost of pipelines and compressors for the offshore hydrogen backbone is estimated to account for 10% of the total cost of hydrogen produced offshore.

The study strengthens GASCADE and Fluxys in their conviction that the AquaDuctus project is a key building block to achieve a green transition and meet the decarbonization targets of the EU Green Deal and REPowerEU package.

This large-scale offshore pipeline project, conceived to efficiently carry hydrogen produced from wind farms in the North Sea onto the German onshore hydrogen grid, is indeed designed as a backbone able to collect hydrogen from multiple production sites while also offering the potential to link up with other international hydrogen flows through the North Sea.

Pascal De Buck, CEO of Fluxys, says:

“The AquaDuctus offshore pipeline, thought as an open access infrastructure available to all future operators of hydrogen wind farms, will make a substantial contribution to security of supply by diversifying Europe’s hydrogen supply sources.”