Azipod® propulsion system ensures high maneuverability and ice-breaking capabilities to support demanding operations, and Onboard DC Grid™ provides enhanced power train efficiency and compatibility with alternative energy sources

Designed for low emissions and energy efficiency, the vessels ensure continuous readiness to keep people, property and nature safe

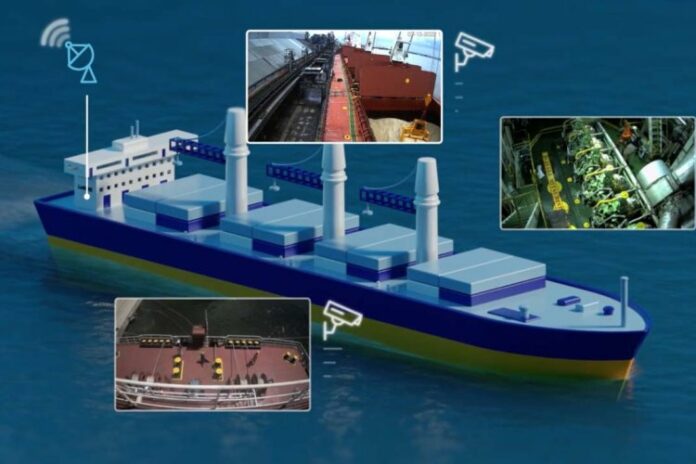

ABB has secured a contract with Finnish shipbuilder Meyer Turku to supply an integrated power and propulsion package comprising two Azipod® propulsion units and the Onboard DC Grid™ power system for two new, advanced multi-purpose patrol vessels of the Finnish Border Guard.

Due delivery in 2025 and 2026, the 98-meter ships will replace the outgoing Tursas and Uisko patrol vessels. Alongside the existing Turva, they will be guarding Finland’s borders, performing maritime rescue operations and helping mitigate environmental impacts. The new vessels will also serve as command bases for other vessels, helicopters, rescue swimmers, divers, and, when necessary, other public security authorities during joint operations. With them, the ability to carry out mass evacuations will grow to more than 400 people and the capacity to collect spilled oil will approximately double from the present level.

Patrolling the Finnish coast, which is characterized by rocky waters, jagged shoreline and challenging winter conditions, sets high demands for the vessels. ABB’s dual Azipod® propulsors will provide the maneuverability and ice-breaking capabilities to optimize performance and safety while enhancing crew comfort by minimizing vibrations.

“Our new patrol vessels will be at sea about 330 days a year, performing operations under busy and diverse conditions,” said Commander Marko Aheristo, Head of Ship Technical Unit at the Finnish Border Guard. “The vessels are designed for low-emission operations and for energy efficiency, and need a versatile and sophisticated power and propulsion system based on advanced, proven technology. ABB provides us with an integrated package that meets our stringent requirements, ensuring rapid functional capacity and continuous readiness to keep people, property and nature safe.”

By increasing power train efficiency and future-proofing the vessels for the adoption of alternative energy sources, ABB Onboard DC Grid™ will help the Finnish Border Guard to meet environmental targets in the short and long term. The system platform’s flexibility will also facilitate the integration of additional mission systems as requirements evolve, while its high fault tolerance and reliability will result in safer, more efficient operations.

Alongside Onboard DC Grid™ and Azipod® propulsion, ABB’s scope of supply includes the Power and Energy Management System (PEMS™). As the core of a vessel’s combined power and control system, ABB’s PEMS™ ensures optimal use of total onboard power resources in a safe, energy-efficient and environmentally-friendly manner.

“We are proud to have been chosen by the Finnish Border Guard for this important and forward-thinking project and look forward to continuing our long-standing collaboration with Meyer Turku,” said Antti Ruohonen, Head of Marine Propulsion, ABB Marine & Ports. “With this order, ABB further demonstrates its position as preferred system integrator for challenging and diverse vessel operations.”