On his return journey from a research expedition in the Antarctic Bellingshausen Sea, AWI geoscientist Johann Klages sent a message in a bottle for his children in February 2023.

He has now received an email from Tasmania: an employee of the Central Coast Council found the message in a bottle during a weekend trip on the west coast of Tasmania in August 2025 – but the letter he sent was returned to the sender despite the correct address.

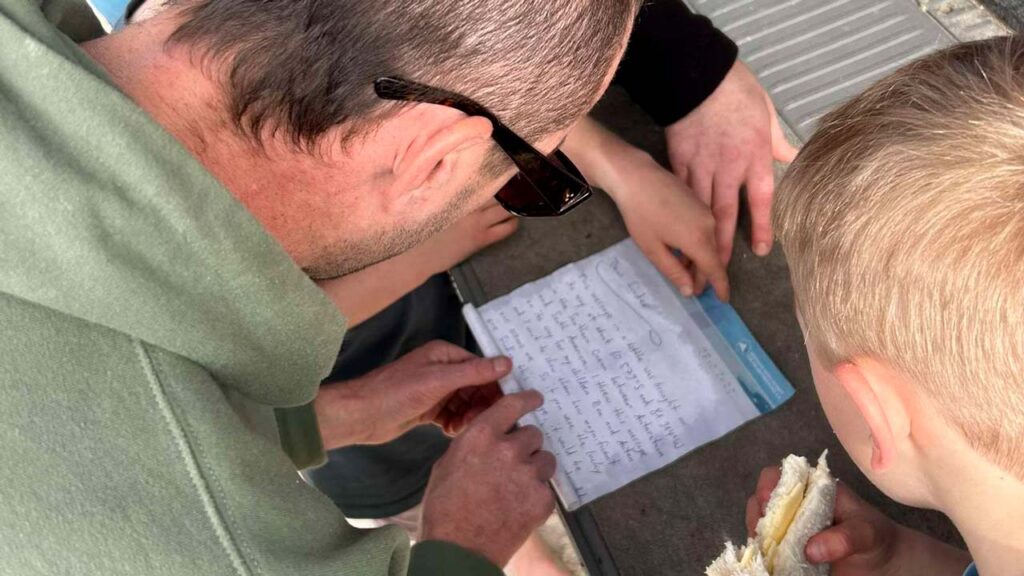

“I was really flabbergasted and so were our children, of course,” says Johann Klages, Marine Geologist at the Alfred Wegener Institute, Helmholtz Centre for Polar and Marine Research (AWI), who took part in a geoscientific expedition on the Polarstern from December 2022 to March 2023. On the return journey to the destination harbour of Punta Arenas (Chile), he had the idea of sending a message in a bottle for his children, who had to spend Christmas without him. So, on 28 February 2023, just north of 60° south in the Drake Passage, he handed over his message to Neptune, the god of the sea, for delivery to an unknown person. Two and a half years later, in August 2025, Toby Ray, an employee of the Australian Central Coast Council, discovered the “parcel” completely intact during a weekend trip to the wild and remote Tasmanian west coast.

“What are the chances?” asks Johann Klages. “Firstly, that the message in a bottle survived the journey, but then also that it wasn’t smashed on the beach and buried, that it was found and picked up. And that the finder even took the trouble to reply.” The latter was anything but trivial: despite the correct postal address, the letter was returned to the sender after three months as undeliverable. This was followed by an online search and contact via email on 9 December 2025.

Then it was up to Johann Klages to surprise the sender: Toby Ray and his family in Tasmania were just as enthusiastic about the fact that he is a polar researcher at the AWI as they were about the starting point.

In the following e-mail exchange, Toby Ray reports on finding the message in a bottle: “I was overwhelmed that I found it at all. Our west coast is rugged and very remote, coming across it is like looking for a needle in a haystack! We were driving along Ocean Beach, the longest beach in Tasmania, when my mate spotted a washed-up buoy. He stopped to pick it up, I was driving alongside him and happened to see the bottle.”

Now he has put another letter in the post, which will hopefully arrive in northern Germany in time for Christmas.

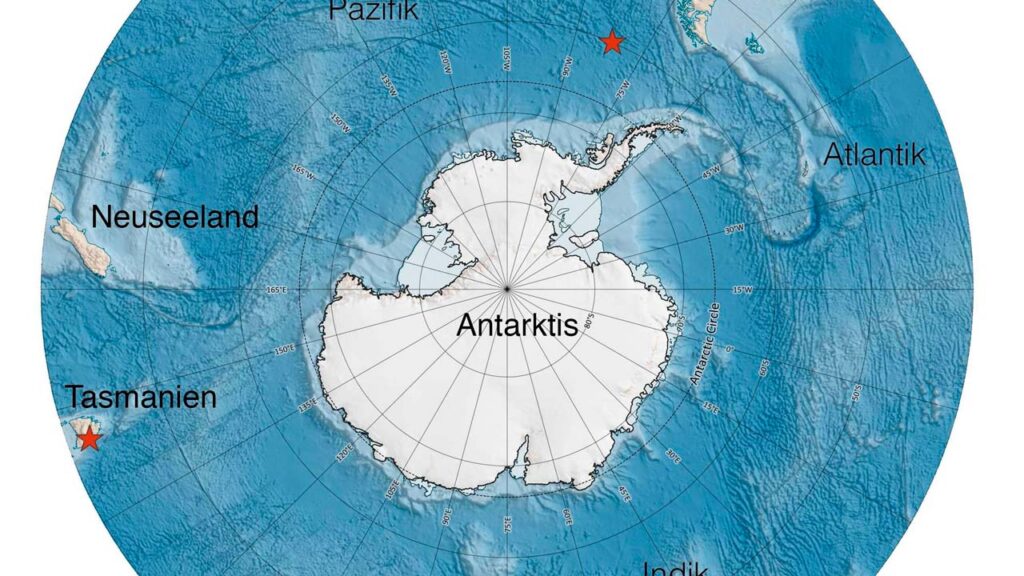

The find is also scientifically exciting: it is clear that it drifted clockwise around the Antarctic continent, as this is the direction of flow of the so-called Antarctic Circumpolar Current (ACC). The message in a bottle needed a maximum of 900 days to travel at least 15,000 kilometres, which would be an average speed of at least 19 centimetres per second, or around 0.7 kilometres per hour. However, the journey was probably much longer, as the ACC has many eddies. A Tasmanian oceanographer, with whom Johann Klages has been in contact, now wants to model how the bottle reached the coast from this ocean current. Both suspect that an eddy caught the bottle and carried it to where it was found.

Toby Ray also reports: “We have a wave rider buoy about ten kilometres from the site that recorded wave heights of 15 metres in the weeks before the find.”

Johann Klages says: “I’m already looking forward to the scientific modelling with the current data during the drift of the message in a bottle, which will still take some time. I’m now looking forward to celebrating Christmas 2025 with my family, where the story of the message in a bottle from three years ago will certainly be a topic of discussion.”