Equinor and Ithaca Energy have taken the final investment decision to progress Phase 1 of the Rosebank development on the UK Continental Shelf (UKCS), investing USD 3.8 billion.

“Developing the Rosebank field will allow us to grow our position as a broad energy partner to the UK, while optimising our oil and gas portfolio, and increasing energy supply in Europe. Rosebank provides an opportunity to develop a field within the UK Continental Shelf which will bring significant benefits to Scotland and the wider UK,” says Geir Tungesvik, executive vice president Projects, Drilling and Procurement at Equinor.

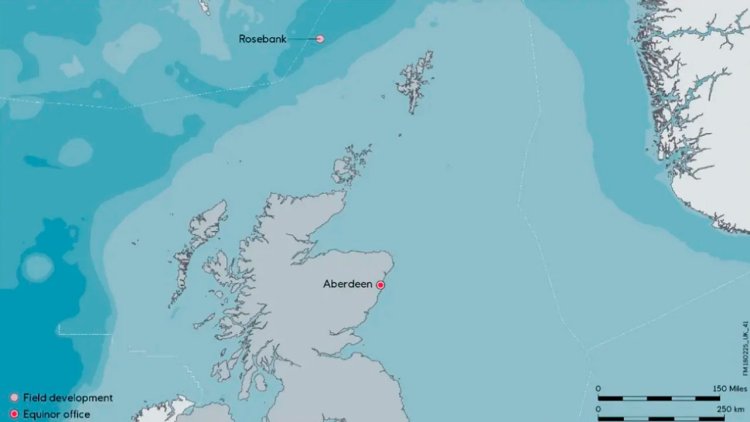

The Rosebank field is located around 130 kilometres north-west of Shetland in approximately 1,100 metres of water depth. Total recoverable resources are estimated at around 300 million barrels of oil, with Phase 1 targeting estimated 245 million barrels of oil.

The field will be developed with subsea wells tied back to a redeployed Floating Production Storage and Offloading vessel (FPSO), with start-up planned in 2026-2027. Oil will be transported to refineries by shuttle tankers, while gas will be exported through the West of Shetland Pipeline system to mainland Scotland.

Philippe Mathieu, executive vice president for Exploration and Production International, says:

“This development further strengthens our international business, and we look forward to collaborating closely with our partner and suppliers to develop and operate Rosebank with the lowest possible carbon footprint while bringing the maximum value to society in the shape of UK investment, local jobs and energy security,” says Mathieu.

The Rosebank oil and gas field is being developed in compliance with the North Sea Transition Deal, an agreement between the UK government and the offshore industry. It acknowledges that whilst there is a continued, though over time reducing need for oil and gas, the remaining demand for oil and gas must be met with the lowest emissions possible.

The FPSO has been designed to be electrification-ready and Equinor is collaborating with government and industry to pursue a regional solution for power from shore to Rosebank and nearby fields to minimise carbon emissions from production.

According to an independent socioeconomic report by Wood Mackenzie and Voar Energy, Rosebank is estimated to create £8.1 billion of total direct investment over the lifetime of the field, of which 78% is likely to be invested in UK-based businesses. It is expected to support around 1,600 jobs during the height of the construction phase of the project, and it will continue to support approx. 450 UK-based jobs during the lifetime of the field.

“We know that the world needs to transition to new, cleaner energy systems and our broad energy investments into the UK support this. And while we do this there is going to be a continued need for oil and gas, which currently meets 76% of the UK’s energy needs. Our decision to progress the Rosebank development is the result of work and collaboration by our employees, partners, government, regulators, and other stakeholders to ensure that this development is able to help meet this ongoing need, with the lowest carbon footprint possible,” says Arne Gürtner, senior vice president Upstream at Equinor in the UK.

TechnipFMC has been awarded an integrated engineering, procurement, construction and installation (iEPCI™) contract for subsea production systems, umbilicals, risers and flowlines with an estimated value of around USD 500 million for the local content part. TechnipFMC has estimated that more than half of the contract value will be generated from local activities across the UK, with a large portion in Scotland.

Project management and engineering activities will be performed mainly from Aberdeen and tree systems will be manufactured in Dunfermline. Umbilicals will be produced in Newcastle, pipelines will be fabricated in Evanton and the main vessel mobilisation site will also be in the UK. In addition, several other fabrication sites in the UK will contribute to the project.