Hyundai Heavy Industries’ new hull design for a low-cost, next-generation deepwater floating LNG vessel has the green light from the American Bureau of Shipping in yet another boost for the offshore delivery of the gas.

The Bureau has granted approval in principle for the design, which the shipbuilder said can be constructed at less than half the cost of a conventional FLNG hull. According to ABS, the hull is based on current designs for LNG carriers, but equipped for LNG production with structural reinforcements to take the loads of heavy topsides. The hull is designed to operate for 25 years without the need for drydocking.

A ready-to-convert offshore FLNG hull opens a whole product line, according to the executive vice-president of HHI’s shipbuilding division, Hyungkwan Kim. “In the current emerging gas market the hull, with ABS certification, at affordable capital expenditure, this is an important product for the monetisation of gas reserves around the globe,” he said.

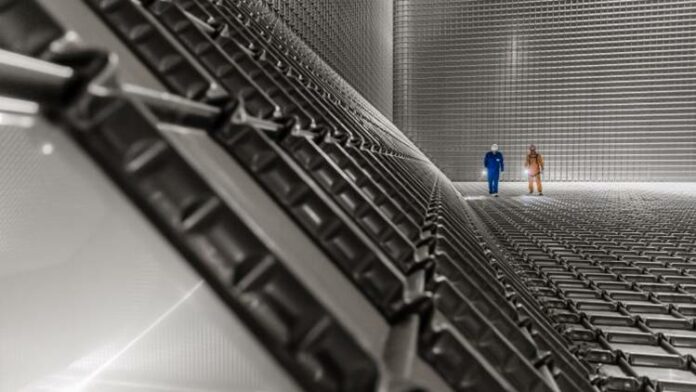

The design features a barge-shaped hull, a GTT Mark III containment system with storage for about 192,000 m3, provision for an internal turret, and 45,000 tonnes of topside structures designed to deliver 2.5M tonnes a year of LNG.

According to ABS, the South Korean group has developed a technically feasible FLNG hull that combines the latest industry trends with first-class shipbuilding practices under ABS rules. Safety standards are high, the Bureau said, and added HHI has a background in low-cost FLNGS. In 2017, ABS approved a near-shore FLNG hull. The two groups – HHI and ABS – have been working on the harsh-environment deepwater hull since then to meet increasing demand.

Source:lngworldshipping