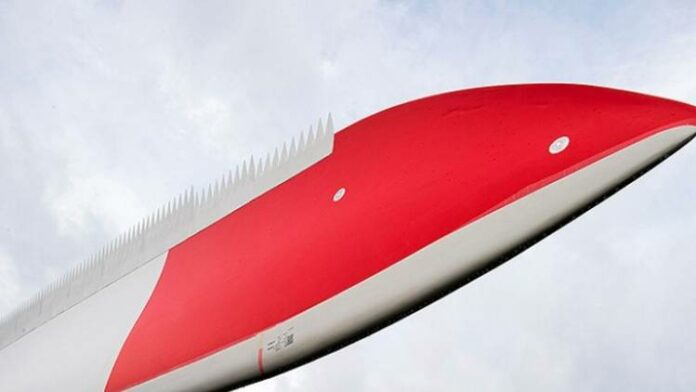

Production of the first wind turbine blade for the 714MW East Anglia 1 (EA1) offshore wind farm has been completed.

Inspection and sign-off of the blade, produced at Siemens Gamesa’s Green Port factory in Hull, north-east England, was completed on 7 February.

In total, Siemens Gamesa is producing 306 75-metre long blades for its 102 7MW turbines for the £2.5bn EA1 project, being developed by ScottishPower Renewables.

The wind farm, which is being built off the coast of eastern England, is due online in 2020.

ScottishPower Renewables EA1 project director Charlie Jordan said: “The manufacture of the first blade from Hull is a fantastic milestone in the development of our wind farm, signalling the start of turbine installation."

The fabrication of the blades from Siemens Gamesa’s facility in Hull further demonstrates our commitment to spending over 50% of the project investment in the UK, ensuring the benefits of East Anglia 1 are felt across the country.

Following production at Siemens Gamesa’s £160m Green Port factory, the blades will be shipped down the coast to Great Yarmouth, where the turbine components will be pre-assembled following a £5m co-investment to prepare Peel Ports Great Yarmouth for construction and installation activities.

ScottishPower Renewables is investing £25m in the Port of Lowestoft with the construction of an operations and maintenance building.

The base, at Associated British Ports’ Hamilton Dock, Lowestoft, will employ 100 staff to manage EA1’s day-to-day operations and maintenance activities.

East Anglia 1 is the first of four offshore wind farms ScottishPower Renewables is developing in the region.

Siemens Gamesa project manager Andrew Elmes said: “The East Anglia 1 offshore wind farm is a world-leading project to be a part of, providing a significant boost to the UK economy and it’s extra special to be able to support it from our amazing factory in Hull.”

Source:renews