Deltamarin has received five Approvals in Principle (AiPs) from DNV and Lloyd’s Register (LR) for its next-generation vessel designs, awarded at Marintec China in Shanghai.

The approved next-generation vessel designs include a 20,000 CBM LNG bunkering vessel, a hybrid and wind-assisted 9,500 CBM liquefied ethylene gas carrier, a 6,200 DWT duplex stainless steel chemical tanker, a 103,000 CBM very large ethane carrier, and an 8,000 TEU methanol-ready container vessel.

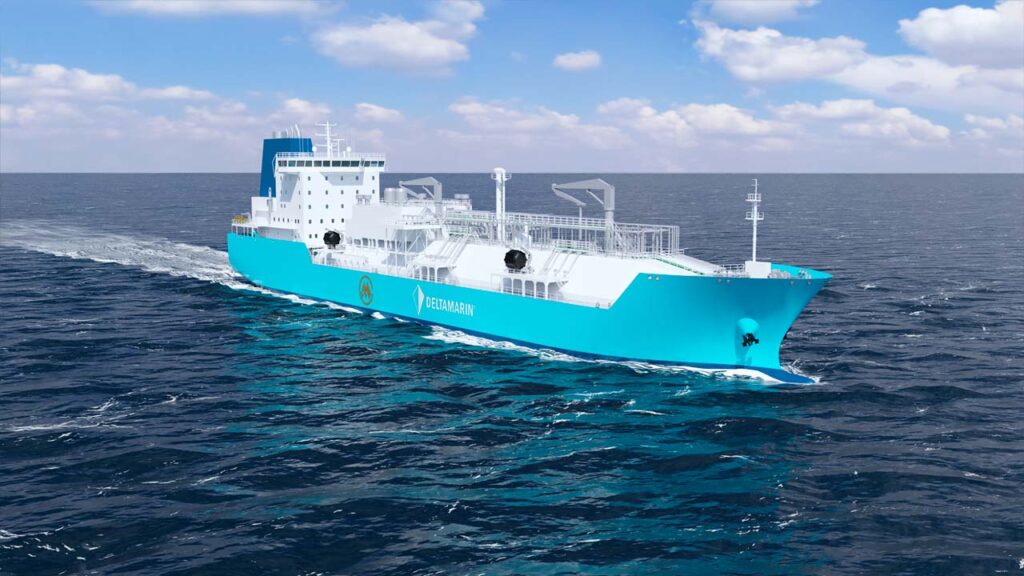

This dedicated LNG bunkering vessel has a tank capacity of 20,000 cubic meters and is designed to supply large-scale liquefied natural gas (LNG) to a variety of large vessels. As a key part of future LNG bunkering infrastructure, the vessel supports the shipping industry’s transition to cleaner energy, enhances safety and operational efficiency, and helps achieve emission reduction goals.

This liquefied gas transport vessel has a capacity of 9,500 cubic meters for liquefied ethylene gas and is designed to operate in Ice Class 1A areas with ice up to 80 centimeters thick. Its standout feature is the “green dual-power system,” which combines battery-hybrid technology with wind-assisted propulsion. This innovative design significantly enhances energy efficiency and represents a new step forward in applying clean energy solutions to small gas carriers.

This small chemical tanker has a deadweight tonnage (DWT) of 6,200 tons and features duplex stainless steel cargo tanks. Its design overcomes the traditional “no redundancy” limitation for small ships: if the main engine fails suddenly, the shaft generator can provide reverse propulsion, ensuring the vessel can return safely. This capability significantly reduces the risk of leaks and environmental pollution from hazardous cargo in the event of engine failure.

Notably, the design strategically leverages the European Union Emissions Trading System (EU ETS) exemption for ships under 5,000 gross tonnage (GT). By optimizing the hull design, the vessel maximizes deadweight to the physical limit of 6,200 tons, offering customers a green transportation solution that balances efficiency, safety, and operational flexibility.

This cutting-edge gas carrier has a tank capacity of 103,000 cubic meters and features an innovative three-tank design. It is specifically built for the safe and efficient transport of gaseous cargo, including liquefied ethane. Its large scale and high efficiency are designed to significantly enhance the efficiency of global supply chain for clean gaseous energy.

This large container vessel has a capacity of 8,000 TEU and features “methanol readiness,” meaning it is technically prepared to use green methanol as a clean fuel in the future. The design reflects a forward-looking approach, supporting the shipping industry’s transition toward decarbonization.

Each AiP recognizes the technical features of Deltamarin’s latest designs—from hybrid and wind-assisted propulsion solutions and enhanced safety redundancy on small tankers to large-scale clean-fuel logistics, high-efficiency ethane transport, and methanol-ready capabilities for major vessel types. These approvals affirm the technical strength and innovative character of our next-generation vessel designs, highlighting their contribution to safer, cleaner, and more efficient shipping.