The comparatively short sailing distances encountered along navigable inland waterways combined with stops at navigation locks enhances the attractiveness of using battery propulsion technology. While the popular electrochemical batteries involve lithium technology and chemical acid technology, other competing batteries operate at elevated temperatures, offer extended service lives utilize involve molten metal energy storage.

Introduction

While electrochemical batteries form the basis of modern mobile rechargeable energy storage technology, thermal energy storage once formed the basis of mobile propulsive energy storage. During the era of coal-fired steam railway propulsion, some short-distance steam locomotives and even some boats operated on stored thermal energy. Saturated water was held at high pressure of 250 psia to 1,000 psia at temperature well in excess of the normal boiling point at sea-level atmospheric pressure, at over 200oC. When the throttle was opened, the drop in pressure inside the storage system resulted in some of the heated water flashing into steam.

Some of the very early short-distance submarines built in America were powered by flash steam that was expanded in cylinders to either drive a propeller or in railway traction, drive railway wheels. Flash steam propulsion proved to be very reliable and incurred very low operating costs. During 1924, efforts in Denmark resulted in the development of molten metal thermal energy storage involving sodium hydroxide to store heat at 300oC and intended to produce steam. In this modern era, solar-thermal power plants include molten metal thermal energy storage to generate electric power after sunset.

Modern High Temperature Energy Storage

During this modern era, there are two very distinctively different approaches to high temperature energy storage. One proven technology involves heat-of-fusion thermal storage that is being utilized at solar thermal power plants. During daytime while the power plant generates electric power for the power grid, part of the power plant directs concentrated solar thermal energy into high-temperature, heat-of-fusion thermal energy storage. Low cost thermal energy storage involves mixtures of naturally occurring sodium nitrate and potassium nitrate. High-performance molten mixtures include sodium fluoride and sodium hydroxide, or lithium fluoride and lithium hydroxide that can produce superheated steam.

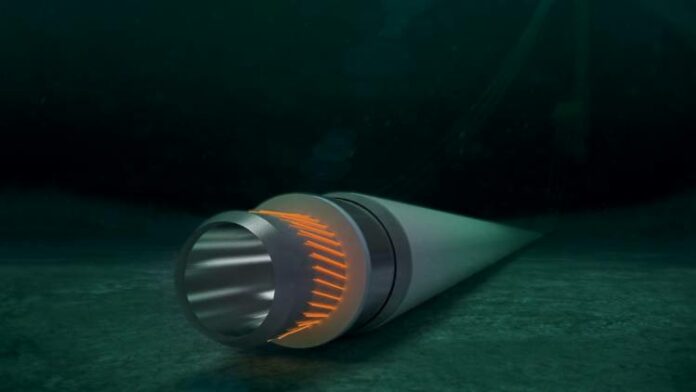

The alternative high-temperature energy storage technology involves electrochemical activity, with the molten sodium-sulfate battery involving a separator to enable controlled electrochemical interaction between molten sulfur and molten sodium. Molten sodium-sulfate technology has been applied to stationary, grid-scale electrical energy storage applications. However, there have been incidents where sodium-sulfate batteries have ignited into flames. The performance of the separator technology is of critical importance to the performance and longevity of grid-scale molten metal batteries. Researchers at MIT working under Professor Donald Sadoway have achieved significant breakthroughs in developing durable separator technology for long-life molten metal battery applications.

Battery Longevity and Cost

Acid based electrochemical battery technologies involve elevated initial and replacement cost with limited usable life expectancy. By comparison, thermal energy storage technology offers greatly extended useble life expectancies and lower long-term costs. The original flash-steam energy storage technology incurred low-cost and greatly extended service life despite tens of thousands of repeated deep-cycle recharges and discharges. Likewise, heat-of-fusion thermal energy storage also offers usable service life expectancies measured in decades, enduring almost infinite deep-cycle recharge and discharge cycles combined with low long-term costs. Molten metal electrochemical energy storage also offers the potential of greatly extended service life at competitive long-term costs.

Stationary Versus Mobile Applications

Both flash-steam and heat-of-fusion thermal energy storage technologies have been used in both stationary and mobile applications. Flash-steam technology delivered reliable performance at low-cost in railway shunting service, with alternative applications in short-distance maritime applications such as tug-boat service. Modern high-performance heat-of-fusion technology involves mixtures of sodium hydroxide and sodium fluoride (295oC). A mixture of lithium hydroxide and lithium fluoride offers storage of over 1100 KJ/Kg at 427oC. While the sodium mixture can provide the heat of vaporization to convert liquid water into saturated steam, the lithium mixture can superheat the steam for efficient expansion in engines.

While molten metal electrochemical storage is intended for stationary applications, there may be scope to adapt the technology for operation along the gentle waters of navigable inland waterways. While researchers believe that the technology may be unsuitable for automotive applications, the technology may be suitable for gentle operation along inland waterways. In stationary applications at some earthquake prone geographic locations, there would be a need for flexible mounting of the battery technology, to compensate for the dynamic shocks and jolts caused by earthquakes. The same mounting technology may be suitable for operation along inland waterways.

Inland Waterway Service

The improved separator technology developed by Sadoway at MIT promises to greatly increase usable life expectancy of molten metal batteries for up to 15 years, greatly reducing battery replacement cost incurred every three to four years. Along some waterways, fully charged batteries would likely partially discharge moving a barge or tow of barges between navigation locks, where partial recharge may either be possible or be available. Short distances of overhead trolley cables could allow for initial acceleration from navigation locks, reducing deep-cycle demand on batteries that could blend in to provide propulsion as the vessel assemble reaches cruising speed.

On the basis of competitive cost and usable life expectancy, molten metal electrochemical batteries that feature improved separator technology become a viable alternative to lithium-based electrochemical storage batteries in both stationary application as well as mobile application along inland waterways. Viable sources of electric power for battery recharge include wind power, solar photovoltaic power, hydroelectric power and ocean kinetic power conversion. Thermal power stations at coastal locations could provide scheduled thermal recharges to tugs utilizing heat-of-fusion thermal storage technology, making them cost competitive with electrochemical battery technology that would also have to obtain energy recharge from thermal power stations.

Batteries in Ocean Sailing

Batteries capable of operating in railway shunting service need to continually endure severe jolts. Compressed air energy storage and flash-steam thermal energy storage batteries are well proven in operating environments that involve severe jolts and would be capable of providing short-distance propulsion through severe wave conditions. Compressed air over water energy storage should prove as rugged in severe conditions. Solid state electrochemical batteries that are well secured to the vessel superstructure and include both solid state electrodes as well as solid state electrolyte would likely withstand the rigors of sailing through severe wave conditions.

Many decades ago, heat-of-fusion thermal energy storage technology was tested in railway propulsion and was capable of withstanding severe jolts. Precedent suggests that there may be scope to adapt modern heat-of-fusion storage technology to ocean going maritime propulsive applications. A large tank of molten sodium mixture to produce saturated steam and a small tank of molten lithium mixture to generate superheated heat could provide many hours of cost competitive propulsive energy, with increasing vessel size extending its operating range to several hundred miles. The suitability of using molten metal electrochemical batteries in ocean sailing is unknown.

Conclusions

While molten metal electrochemical batteries have been developed for stationary grid-storage applications, there may be scope to adapt the technology as energy storage for maritime propulsion along the gentle waters of navigable inland waterways.

Maritime application could accommodate the weight, volume, insulation requirements and energy density of 1MWhr per 1,000 cubic feet of molten metal electrical batteries.

Advances in separator technology undertaken at MIT in the U.S. promises to greatly increase usable service life and decrease the long-term cost of molten metal electrochemical batteries, making the technology competitive with lithium technology.

Heat-of-fusion thermal storage technology would also likely find application in maritime propulsion and especially near coastal thermal power stations.

Source:maritime-executive